The flash flow time constant in LED lighting technology

1. Preface The significant percentage respect to the initial luminous flux emission The continuous growth of LED lighting is significantly...

1. Preface

The significant percentage respect to the initial luminous flux emission

The continuous growth of LED lighting is significantly transforming the lighting industry, providing a range of millions of colours and dynamic effects that conventional lighting cannot match in terms of design. Furthermore, the miniaturization of the dimensions and the low thermal radiation allow LEDs to be incorporated almost everywhere. In addition, ensuring a long life together with energy and management savings, they offer potentially efficient lighting solutions.

However, there is a problem: in recent years the market has been invaded by a large number of new unknown operators, with questionable information about the performance of their products, too much optimistic to be true and even technically unsupported.

The need for accurate information leads designers and end users to demand the characteristics of such new lighting systems in order to be able to adequately assess how long a LED device keeps a significant percentage of the initial emission of light during the years of operation and depending on the so-called "child mortality" or sudden failure.

2. The dimensional criteria

In the standardization process, there are three elements that can be standardized, such as:

- Technical definitions

- Measure methods

- Limit values.

The performance prescriptions described in the IEC standards provide a definition of qualitative criteria and how to measure them.

The lifetime of LEDs is, in most cases, longer than practical test times. Consequently, verification of manufacturer's claims on life expectancy should be considered as indicative, because based on extrapolations not yet validated by durability tests as other components concur in the supply circuitry.

In order to substantiate a life-long statement, extrapolation of test data is required. In this respect, a general method is being studied to allow the projection of measured data over the limited time of the test.

The IEC Regulations propose the following list of qualitative criteria to be considered when evaluating manufacturer's declarations:

- Nominal absorbed power. The nominal power absorbed is the indication of the amount of energy consumed by a lighting equipment, including its power supply. That rated power is expressed in Watts.

- Nominal luminous flux. Corresponds to the amount of light emitted by the lighting fixture and it is expressed in lumens "lm" (light emitted). Since the normal life of a LED lighting fixture is very long, it is need a long time to measure the flow reduction during the lifetime (for example L 70 means the period during which the LED module provides more than 70% of the initial flow). In addition, the actual LED behaviour in terms of flow maintenance may differ considerably depending on the type and on the manufacturer. To validate a statement of life, extrapolation of test data is required. IEC is currently studying a general method for data measurement beyond the limited time of testing. In the USA, a LM-80 test data extrapolation is included in IES TM-21. Instead of validating the lifespan, the IECs opted for the flow maintenance codes at a definite test time. Therefore, the code number does not imply a prediction of the possible lifespan, so the categories are identified by a character that expresses the depreciation of the flow in accordance with the information that is provided by the manufacturer prior to the start of the test.

- Efficiency of LED device. It is the initial measured luminous flux, divided by the initial absorbed power measured, lumen/Watt "lm/W".

- Distribution of light intensity. It is the spatial distribution of the luminous flux that is graphically represented in a luminous intensity distribution curve, which is usually expressed in a polar coordinate diagram representing the luminous intensity as a function of the angle from the light source. It is expressed in cd. The unit-level candle is defined as the amount of illumination that the inner surface of a sphere at one foot should receive if, at the exact point of the sphere, there was a uniform point source of a candle. Alternatively, it can be defined as illumination on a square meter surface with a uniformly distributed lumen flow.

- Photometric code. It is the six-character code that indicates the fundamental parameters of light quality: CRI, CCT, colour coordinates and luminous flux, where:

- Colour Temperature (CCT) is the colour temperature of a white LED module and it is determined by comparing the light emitted by a LED module with the light of a black body (ideal radiator at a given temperature). It is expressed in Kelvin degrees.

- Colour rendering index (CRI) is the colour rendering of a white light LED module. This is the effect of objects the colour appearance by conscious or subconscious comparison with their colour appearance under a reference lighting source.

- Nominal values of the initial colour coordinates and maintained over time. This is the variation of the colour coordinates of a LED module expressed in two measurements both initial and maintained.

- Flow maintenance code. It is the initial measured luminous flux (initial value), standardized at 100% and used as the starting point for LED life determination. The maintained luminous flux is measured at 25% of rated life up to a maximum of 6,000 hours and it is expressed as a percentage of the initial value. The retained value determines the flow maintenance code.

- The nominal life (in h) of the LED module is the associated value of maintaining the rated luminous flux (Lx). It is the length of the period during which a group of LED modules provides more than the declared percentage (x) of the initial luminous flux always shown in combination with the rate of failure. It is expressed in hours.

- Fault fraction (By), which only expresses the gradual degradation of light output as a percentage "y" of a number of LED modules of the same type that at their nominal duration indicates the percentage (fraction) of the failure. The value B50 indicates that the declared L value will be reached by at least 50% of the LED modules and that the remaining 50% may have a lower lumen value. Or the value B10 means that the least 90% of the LED modules will satisfy the declared L value and only 10% will have a lower flow level. So you can clearly deduce that the more the B value is, the more it will be conservative for the purpose of the functional guarantee.

- Fault fraction (Cz) expresses only the abrupt deterioration of the light output as y percentage of a number of LED modules of the same type which, at their nominal duration, indicate the percentage (fractions) of the failures. A catastrophic failure is when the LED module does not emit any light.

- Fault Rate (Fy), represents the fraction of combined failure. This is the incremental (By) and total (Cz) combination of failures at the nominal life of the LED module in the equipment.

- Room temperature (s) of the equipment. It’s the temperature of the environment surrounding the lighting fixture linked to a specific performance. For a given performance the ambient temperature (ta) is a fixed value. It is possible to declare performance specifications at different temperatures.

- Colour Temperature (CCT) is the colour temperature of a white LED module and it is determined by comparing the light emitted by a LED module with the light of a black body (ideal radiator at a given temperature). It is expressed in Kelvin degrees.

- Colour rendering index (CRI) is the colour rendering of a white light LED module. This is the effect of objects the colour appearance by conscious or subconscious comparison with their colour appearance under a reference lighting source.

- Nominal values of the initial colour coordinates and maintained over time. This is the variation of the colour coordinates of a LED module expressed in two measurements both initial and maintained.

- Flow maintenance code. It is the initial measured luminous flux (initial value), standardized at 100% and used as the starting point for LED life determination. The maintained luminous flux is measured at 25% of rated life up to a maximum of 6,000 hours and it is expressed as a percentage of the initial value. The retained value determines the flow maintenance code.

3. Declarations about the maintenance of the light flow

Currently, several LED lighting manufacturers produce test results according to the LM-80 as the basis for Lx, By and Cz statements as maintenance thresholds for LED lighting fixtures.

The LM-80 requires to test LEDs for 6.000 hours and recommends testing for 10.000 hours. It requires tests at three surface temperatures (55°C, 85°C and a third temperature determined by the manufacturer) to see the effects of the temperature on the light output and specify the additional test conditions to ensure consistent and comparable results.

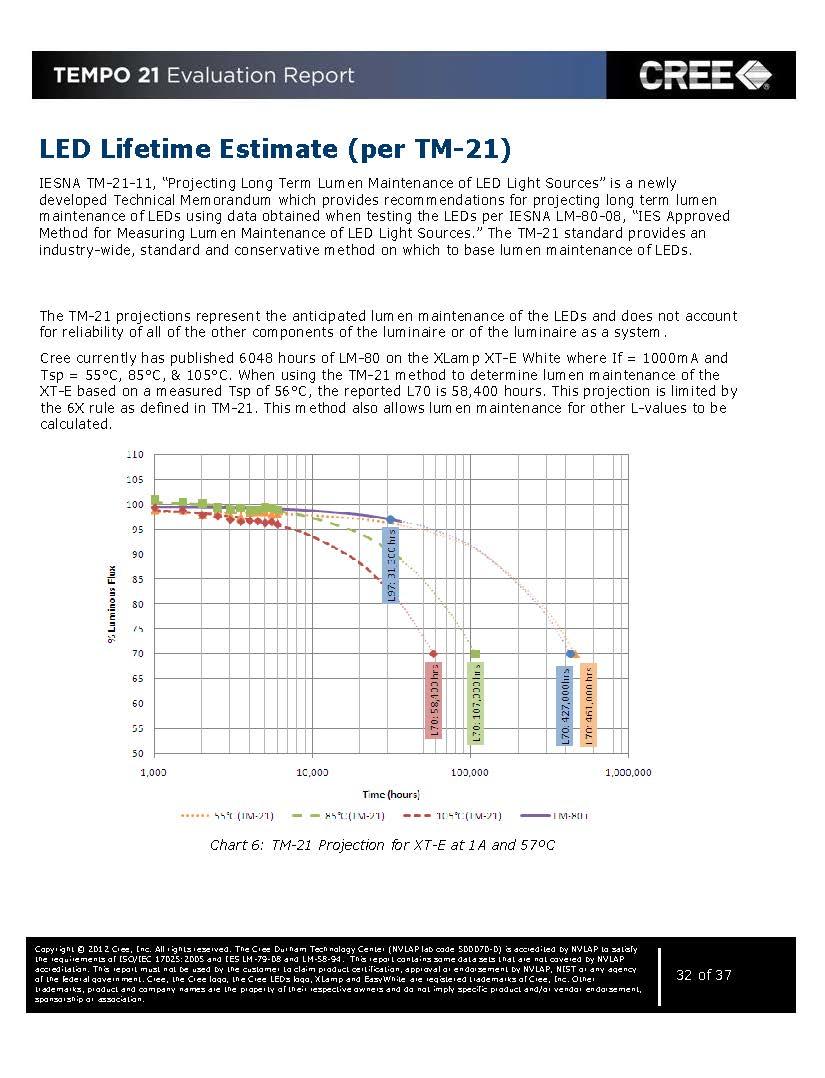

In fact, the main LED manufacturers try their products at the minimum of 6.000 or 10.000 hours provided by the LM-80, and then apply extrapolation methods as described in TM-21 (see Reference Table below) to get the values L90, L70 and L50. The device manufacturers translate these curves into specific curves of the LED lighting fixture.

For a better understanding, see below an extrapolation diagram, (source CREE) and the reference regulations.

IES LM-79-08: Approved Method: Electrical and Photometric Measurements of Solid-State Lighting Products – Illuminating Engineering Society of North America, 2008

LM-79: Prescrive i metodi di prova uniformi in condizioni controllate per le prestazioni fotometriche e colorimetriche, nonché le misure di potenza elettrica degli apparecchi di illuminazione a LED. Questa può essere usata per misurare le specifiche iniziali elettriche e fotometriche di un apparecchio LED.

IES LM-80-08: Approved Method: Measuring Lumen Maintenance of LED Light Sources – Illuminating Engineering Society of North America, 2008

LM-80: Regarding the measurement of the luminance maintenance of LED light sources (single LEDs or multi chips). It consists of a real size for the first 6.000 hours, combined with an extrapolation until the end of life. Many lighting fixture manufacturers translate the LED light source curve in the illumination LED device maintenance curve using the TM-21 recommendations.

There are two constraints:

- First: the sudden failure of the individual LEDs and other failure modes that contribute to the decay of the LED's luminous flux in a lighting fixture are not taken into consideration.

- Second: There is no valid method to translate the flow curve of individual LEDs into the curve of the lighting fixture.

IES TM-21-11: Projecting Long Term Lumen Maintenance of LED Packages – Illuminating Engineering Society of North America, 2011

TM-21: Provides recommendations for the long-term projection of LED luminous flux maintenance using the data obtained during tests in accordance with IES LM-80-08

4. Conclusions

The life of the LED module and power supply unit should be stated separately. If the lifetime of the power supply is shorter than LED, replacement of the power supply will be necessary before the lifetime of the unit is completed. This means that there is no unicity in the statement of the lifespan of the lighting equipment. A useful metric for "median useful life" has been introduced in IEC 62717. This is the time elapsed until the 50% of the LED lighting fixtures in use reach the declared light flow, for example L80.

Most manufacturers state in the catalogue the parameters, referring to 100% of the initial light flux:

L70 B10 C10, where:

L70 indicates the percentage value of maintenance under operating conditions with respect to the initial light flux and operating temperature.

Eg.1: If at 25°C a LED declares 100.000h of life, L70 indicates that it will be able to guarantee 70.000h (70% of the nominal value)

Eg.2: If at 45°C a LED declares 90.000h of life, L70 indicates that it will be able to guarantee 63.000h (70% of the nominal value)

Eg.3: If at 60°C a LED declares 50.000h of life, L70 indicates that it will be able to guarantee 35.000h (70% of the nominal value)

B 10 indicates the percentage value of the lighting fixtures that are supposed to be extinguished under operating conditions with respect to the initial light flux and operating temperature.

E.g.: In case of malfunction, B10 indicates that the luminous flux, in its overall circuitry, may decrease depending on the remaining number of lighting equipment on (possible 10% decrease compared to the initial volume).

C10 indicates the percentage value of the lighting fixtures that may break down and not to re-start in operating conditions with respect to the initial quantity.

E.g.: In the event of a definite failure, C10 indicates that the luminous flux, in its overall circuitry, may decrease as a function of the remaining number of lighting equipment (possible 10% decrease compared to the initial quantity).

Cortem Group, according to the type of lighting fixtures and the built-in LED model installed, has designed and manufactured specific housings suitable for the dissipation features required by the manufacturer of LEDs, in order to dissipate LEDs heat generated during operation and thus optimizing, during the engineering phase, the ability to last in time with the least power and luminous flux loss.

In addition, always paying close attention to the functional guarantee and the end-of-life aspect, Cortem Group analysed all the constructive and product quality variables, in order to minimize possible defects resulting from so-called "child mortality" and possible implications for a proper dimensioning of the drivers, for uses in environments with positive or negative temperatures.

All of the above considerations are of an exemplary nature and they are not intended for a specific product of Cortem. For each specific product is necessary to refer to the technical data sheets.