The function of cable glands

Methods of use and installation The cables entry into electrical explosion-proof junction boxes suitable for areas with hazardous...

The cables entry into electrical explosion-proof junction boxes suitable for areas with hazardous atmosphere can be performed in several ways in compliance with EN 60079-14 standard.

In particular, the systems most used are:

- conduit system with sealed joint;

- cable system with Ex cable glands with sealing ring;

- cable system with Ex sealed cable glands.

We have already discussed in previous newsletters about conduit systems and about the use of sealing fittings.

In this article, we will speak about cable systems with the use of cable glands.

Cable glands must be constructed according to the Ex "d" method of protection, meet the requirements of EN 60079-1 standard and must be certified and marked.

Depending on the type of use, they can be with compression ring and barrier.

These categories are divided, according to the cable used, into:

- for armored cable;

- for non-armored cable.

1. Cable glands with compression ring

Cable glands must be chosen considering the cable diameter. The tightness is ensured by the compression of a rubber gasket that tightens on the external diameter and prevents the flame from spreading elsewhere.

Usually, the sealing ring is as long as the flame-path. Minimum and maximum diameters of the use of the cable are reported on the sealing rings. It is forbidden to insert more cables into the same cable gland, as well as to increase the sealing ring diameter with insulating tape or similar, in order to make it match with the sealing ring diameter.

Cable glands for armored cables have two sealing rings: the front one tightens on the internal diameter and guarantees the explosion-proof protection; the rear one tightens on the external diameter and prevents liquids from penetrating into the cable gland, where the armor is sealed by two conic rings guaranteeing the electronic continuity of grounding.

If the cable gland is removed for system maintenance, will be necessary to replace the selaing rings because they could not be more reliable.

2. Barrier cable glands

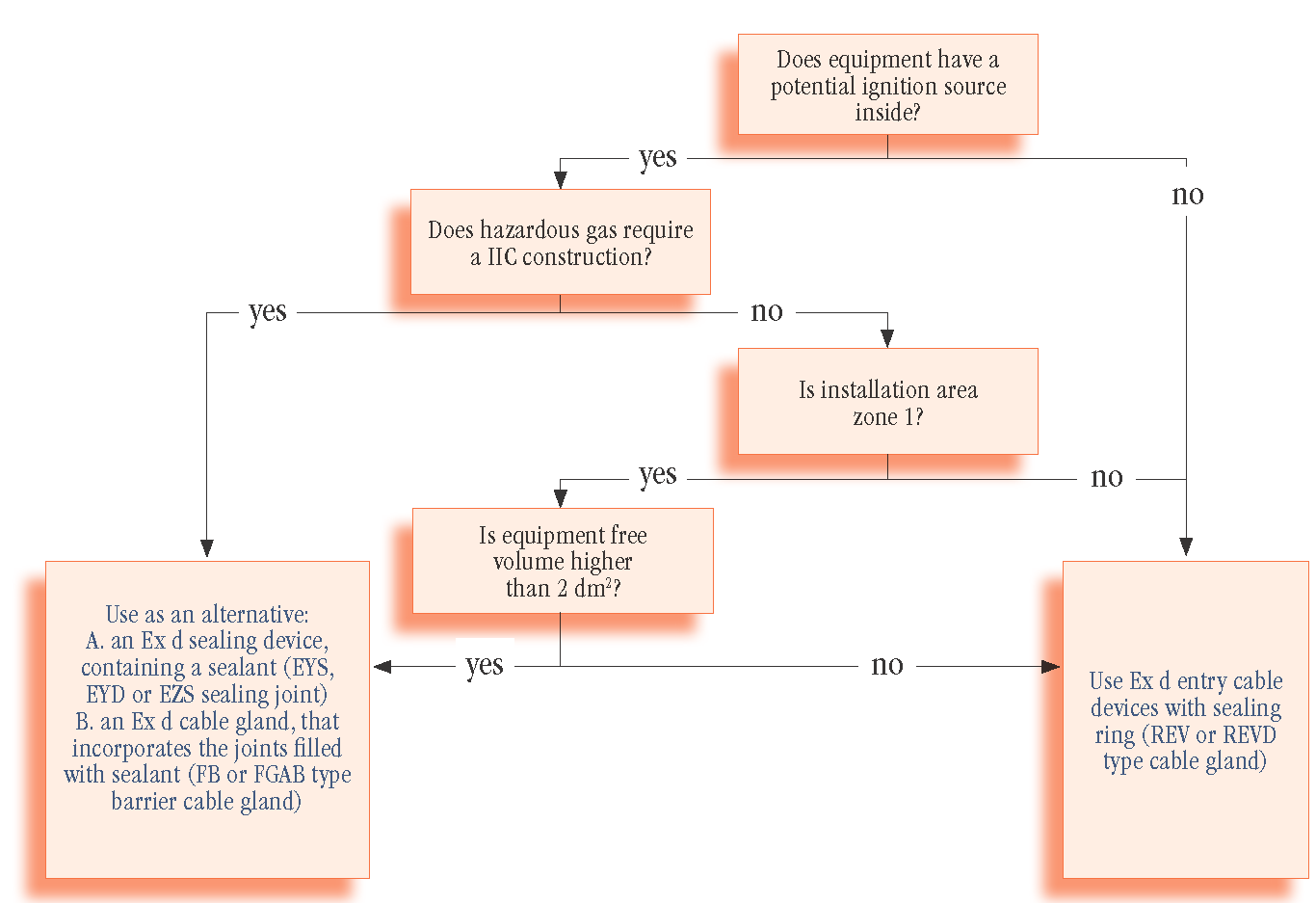

Cable glands with sealing rings can not be used in certain conditions. The diagram below, introduced by EN 60079-14 standard, shows the flow chart for the correct selection of the cable entry.

If the gas group is IIC, if you are in Zone 1 or if the volume of the explosion-proof enclosure is higher than 2 dm3 you must use "barrier" cable glands.

In this case, the cable is sealed by a resin in a sleeve which, when inserted into the gland, form a flame-path with the internal part of the body.

In this case, the cable gland can be disassembled and reassembled during maintenance without any problem, just verifing that the flame-path surfaces are intact.

3. REV and REVD series clable glands for armoured and no-armoured cables

REV and REVD series cable glands are suitable for use in hazardous areas with danger of explosion to enable direct insertion of non-armoured cables, REV series cable glands, and of armored cables, REVD series cable glands, into explosion-proof junction boxes and/or lighting fixtures, plugs and sockets, etc...

The new cable glands series has optimally exceeded all the tests currently required for the certification of this product. The result is a cable gland of highest performance in terms of reliability and safety, able to cover a wide range of the main cables on the marked such as plaited armoured cables, flat or wire cables.

REV and REVD series is more competitive and, at the same time, more powerful than the cable glands of the previous series.

The most important innovation is the use of one sealing ring on the inner and outer sheath of the cable and no longer a kit of sealing rings of different diameters. REV series is constituted by a single sealing ring which tightens the incoming cable ensuring the 'Ex d' method of protection and IP66/67 degree of protection. REVD series has a second sealing ring that tightens on the outer sheath of the cable to ensure the IP66/67 degree of protection avoiding the ingress of water, moisture, rain and dust. The cable range available for each cable gland is described in the following tables.

A further advantage is the lighter weight and the smaller dimensions, an important detail when there’s the need to install a large number of cable glands on explosion-proof enclosures.

The new cable glands REV and REVD series have been designed to replace FL/FG e FAL/FGA series cable glands. They are realized in NICKEL-PLATED BRASS, STAINLESS STEEL and GALVANIZED STEEL from 3/8" up to 2” and in NICKEL-PLATED BRASS and STAINLESS STEEL from 2 1/2” up to 4".

This new series includes also REVL, REVDL series special version which can accommodate smaller cable diameters than the standard required for each measure. In this way, the use of reductions is avoids.

The new cable glands of REVF and REVN series are designed to replace the FGF series (female threaded entry) and the FGN series cable glands (male threaded entry) available from 3/8" to 2" sizes and made of NICKEL-PLATED BRASS, STAINLESS STEEL and GALVANIZED STEEL. It’s also available a waterproof series with IP66/67 protection degree: TEV series for non-armoured cables and TEVD for armoured cables.

They are provided with high-tech and high mechanical performance compression rings and gaskets with high-temperature resistance.

Thanks to their structure, they are particularly suitable both in harsh application, such as marine one, and places subjected to stress and mechanical shock as often happens in all those places of the “heavy” industry where safety is a top priority.

The new series has three types of protection 'Ex d', 'Ex e' and 'Ex tb'. It can be also used in ‘Ex i’ intrinsic safety circuits. In this case, the cable glands have a part painted light blue.

The evolution of the marking has allowed us to create a transparent polyester label which has stood very well the various tests of salt corrosion, durability in harsh environments and high temperatures, impact resistance.

In order to ensure a greater security and reliability of its cable glands, Cortem Group, in addition to mandatory certification tests, submits its products to further harsher tests. It evaluates the resistance of its cable glands to a traction test without fixing the cable armour and with much higher load values (up to an extra 50%) than required by the standard.