Typical connections of 'Ex eb' junction boxes into 'Ex db' and 'Ex eb' motors

In this article, we will delve into the connection of 'Ex db' and 'Ex eb' electric motors with 'Ex eb' junction boxes to the power line using electrical connection accessories, i.e. adapters, sealing fittings, cable glands and flexible tubes. Being able to use an Ex-eb cable gland is not at all negligible from an economic point of view. The time saving during installation compared to installing a sealing fitting or an Ex-db cable gland is considerable.

by Andrea Battauz, R&D Manager of Cortem Group

Premise

In the previous article "Accessories for connecting flameproof motors" we analyzed the choice of fittings suitable for connecting flameproof motors with Ex-db connection box.

In practice, installers on construction sites often have to seal barrier cable glands or to cast the sealing fittings in narrow places. Cables, which are often armored and have limited bending ability, add further difficulty to the installation.

Manufacturers therefore have flameproof electric motors with increased safety connection box in their catalog’s which facilitate the connection of this equipment to the power line. Then there are the increased safety motors which, as would be logically expected, have the connection box made with the same type of protection.

In this article, we will delve into the connection of 'Ex db' and 'Ex eb' electric motors with 'Ex eb' junction boxes to the power line with regards to the use of electrical connection accessories, i.e. adapters, sealing fittings, cable glands and flexible tubes.

In this regard we will give some examples of system applications, remembering that the choice of these accessories, as well as for cables, is the responsibility and responsibility of the designer who must scrupulously apply what is foreseen by the applicable IEC/EN 60079-14. [1]

The increased safety connection box

The flameproof electric motor with Ex-eb connection box is a typical example of a composition of types of protection.

The volume that houses the rotor and stator is flameproof according to EN/IEC 60079-1 while the connection box is separate, the motor's electrical connections are separated by means of a sealed flameproof bushing passage. These cable passages allow to contain a possible explosion that occurs inside the motor casing avoiding it expands to the connection compartment.

Connection using cables with external sheath [2]

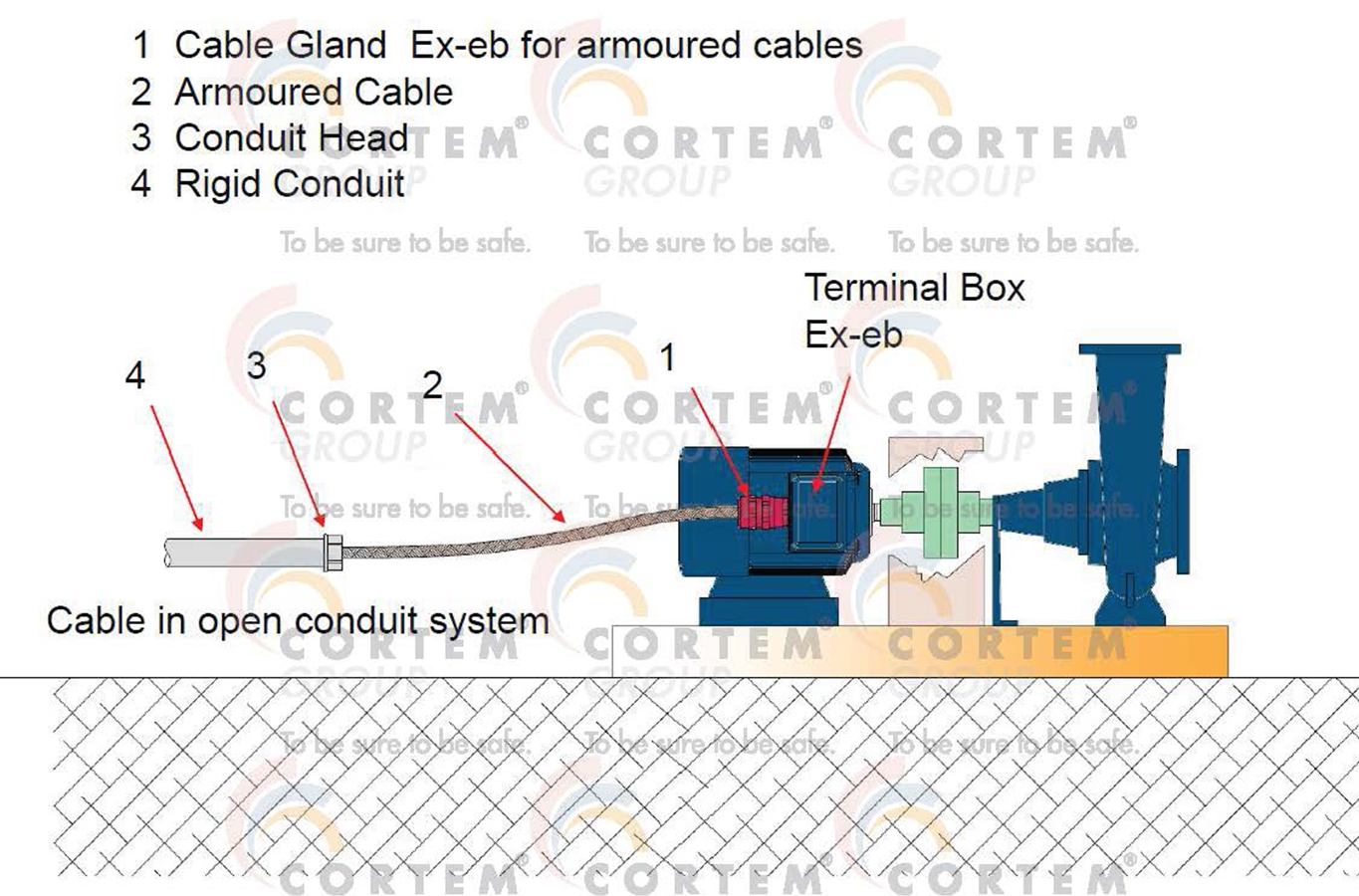

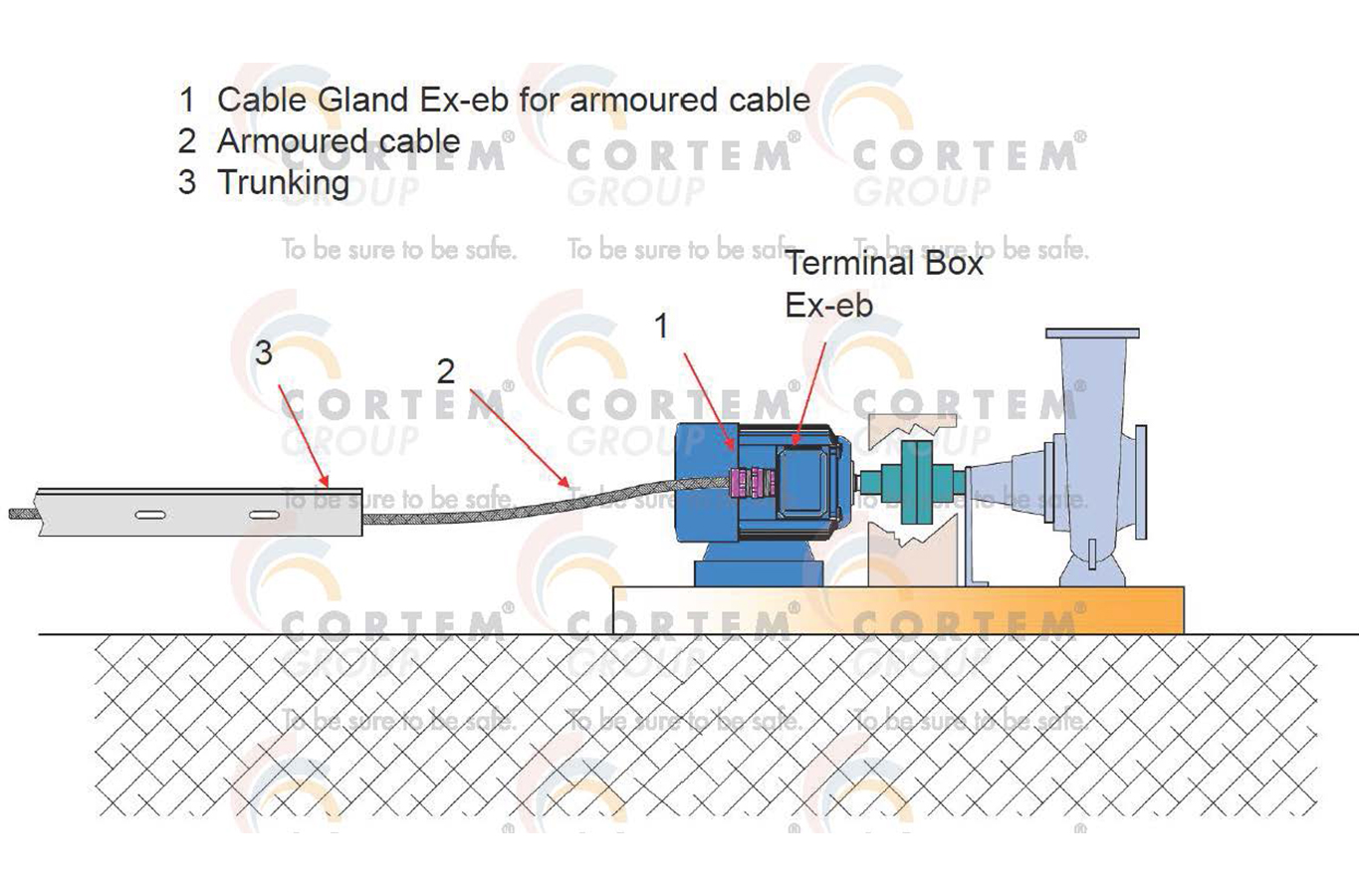

Figures 1 and 2 show the connection of a motor with an increased safety connection box. The cable gland used is Ex-eb certified and, in this specific case, is suitable for use with armored cable.

The use of armored cable is not a requirement of the Ex-regulation but rather a concept of mechanical protection that is present in industrial regulations, national legislation, and engineering specifications.

In figure 1, the cable is laid in a conduit tube which is part of a system defined as "cable in open conduit", i.e. where the metal tube is used for mechanical protection only. Figure 2 shows the same accessory diagram but with the cable coming out of the motor and resting in the raceway.

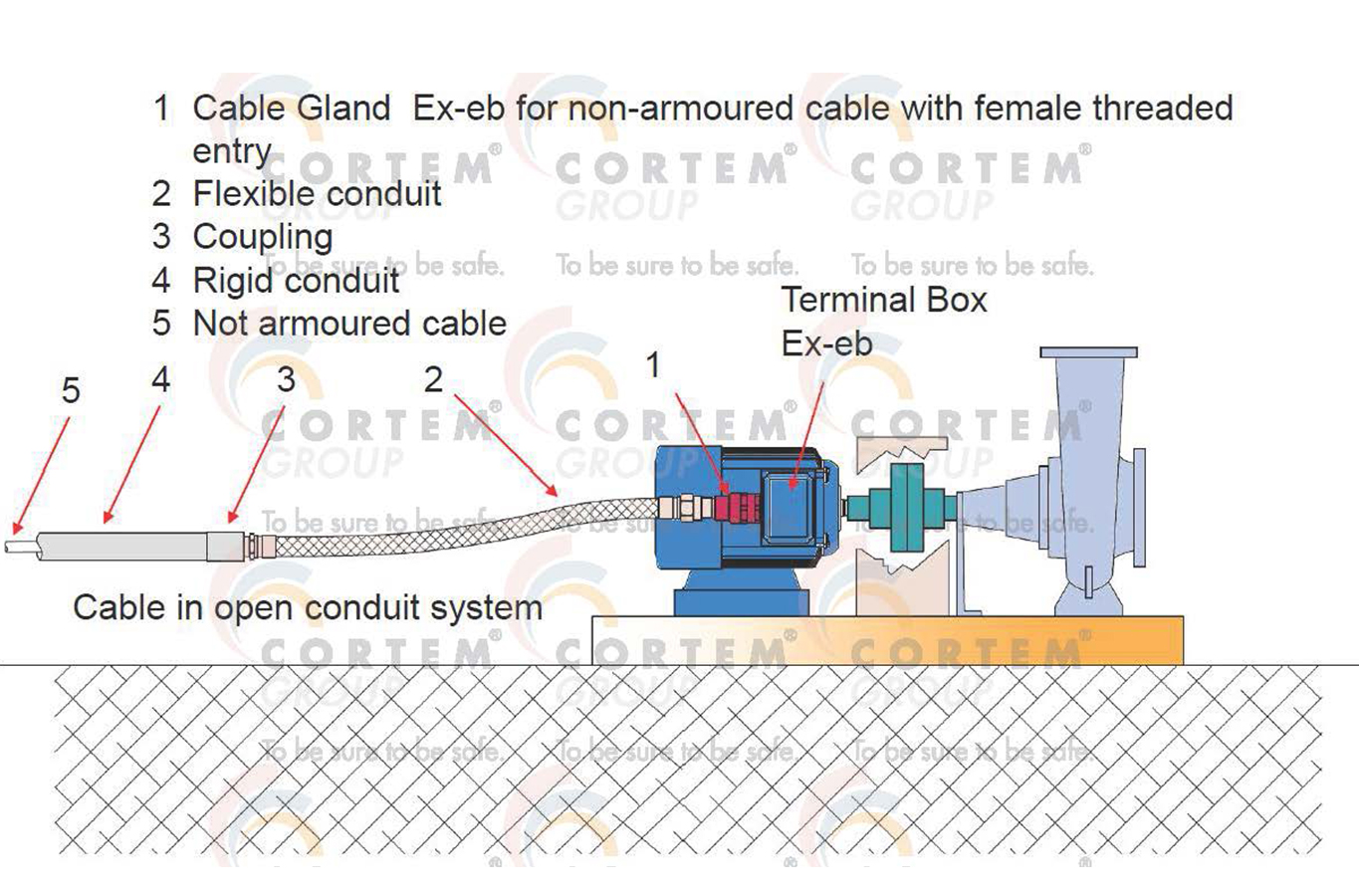

In figure 3, there is a mechanical protection of the cable, in this case unarmored, through the connection of the motor with a flexible tube which reduces the transmission of vibrations to the metal structure of the pipes. In figure 3, the IP seal of the terminal box is guaranteed by the cable gland seal on the external sheath of the cable, the conduit tube, shown here, is part of an open conduit system, like that of figure 1. To facilitate the assembly, the flexible tube or the cable gland with female entry can be equipped with a free-rotation part.

Figure 1 : Example of connecting a motor with Ex-eb connection box with an Ex-eb cable gland with cable in open conduit system

Figure 2 : Example of connecting a motor with Ex-eb connection box with an Ex-eb cable gland.

Figure 3 : Connection example of a motor with Ex-eb connection box with an Ex-eb cable gland and flexible tube.

Conclusions

We have examined some typical examples of installation of motors used in Ex regulation systems (ATEX and IECEX). We can therefore understand the added value of equipment furnished with an increased safety connection terminal box.

Being able to use an Ex-eb cable gland is not at all negligible from an economic point of view. The time saving during installation compared to installing a sealing fitting or an Ex-db cable gland is considerable. Furthermore, although the latest edition of IEC/EN 60079-14 has expanded the use of Ex-db cable glands with gasket, these cannot be used with all types of cable.

Notes and bibliography

[1] IEC/EN 60079-14 par. 10.6.2

[2] The minimum requirements of these cables are the flame retardancy characteristics as required by par. 9.3.9 of EN/IEC 60079-14 and tensile strength, the so-called “easy tear” cables compulsorily require the use of a conduit (par 9.3.1 of EN/IEC 60079-14 and par 9.4.1 of CEI 31-108)