“Ex eb” increased safety component enclosures IECEX certified for Zone 2

Even for installations in Zone 2, what we have already highlighted for Zone 1 applies: the list of components in the certificate or in the use and maintenance manual is the attestation that the installation of a certain certified component has been assessed by the notified body.

by Andrea Battauz, R&D Project Engineer of Cortem Group

Premise

In many systems there is the requirement to install panels suitable for installation in an area classified as Zone 2 due to the risk of explosive atmospheres.

One possibility is to use Ex -db explosion-proof enclosures with a higher degree of protection (EPL Gb) and with the advantage of having greater freedom in the choice of installed components. In fact, in explosion-proof enclosures, components suitable for the industrial standard can be installed internally, respecting some rules, since the explosion protection is provided by the enclosure. Enclosures like these are, however, heavier and more expensive than the increased safety Ex-eb ones [1]. Furthermore, the latter can also be made of GRP plastic material which, in certain contexts, may be required by the engineering specifications of the end customer.

In these implementations, it is necessary to find components suitable for use in Zone 2 consistent with the regulatory status quo. Furthermore, according to the IECEX regulatory scheme, [2] it is necessary that they are listed within the enclosure certificate with components [3], a certificate which will then be cited on the equipment plate of the enclosure.

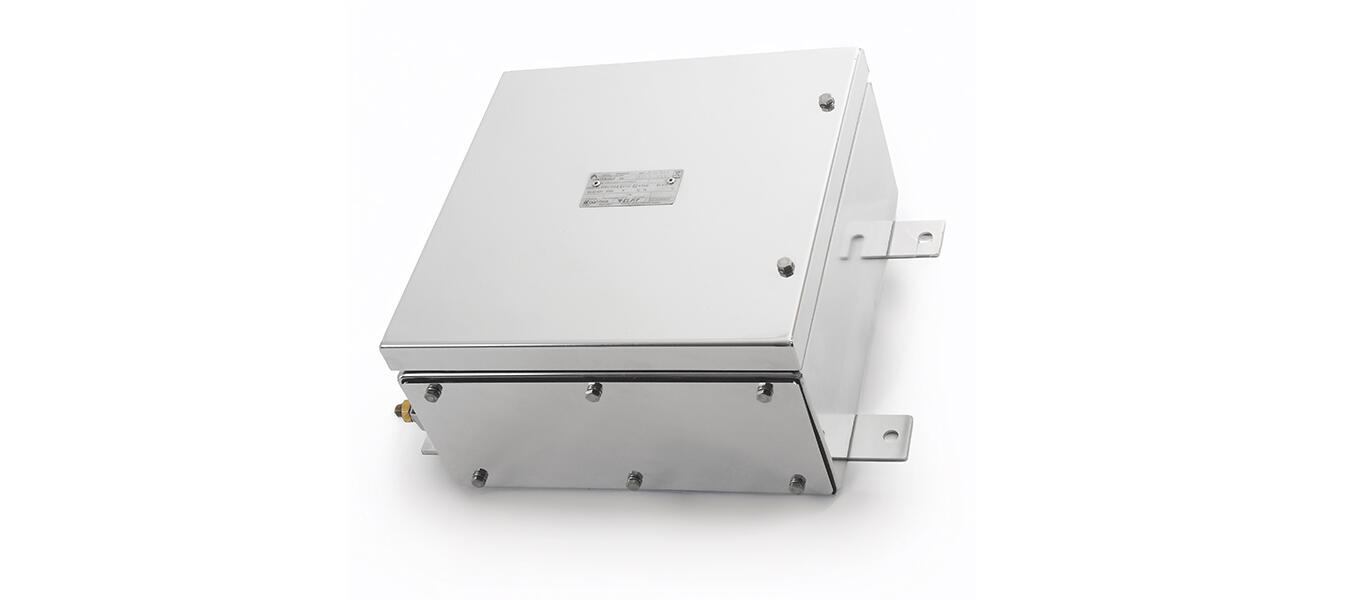

Figure 1: CORTEM CTB enclosures have been IECEx certified for use with various components in Zone 2(IECEX CML 23.0003X)

The list of certified components in the custody certificate with components suitable for Zone 2

Strange as it may seem, an installation in Zone 2 can be more complex to implement than a similar application in Zone 1, which we've already covered in detail on our website. Increased safety enclosures (Ex eb ) for Zone 1.

The fact that in Zone 2, according to the ATEX directive, for category 3 electrical equipment it is sufficient to create and maintain the technical file in the company, without involving a notified body [2], makes the selection of components more complicated. In the European market, the latter do not require a certificate, while according to the international IECEX scheme, a certificate issued by a notified body is always necessary.

This regulatory misalignment does not exist in Zone 1, where Category 2 electrical equipment, as required by the IECEX scheme, requires a certificate issued by a notified body.Components often required for installation in Zone 2 include: HMI [4], PLC, switches and network modules, power supplies, relays , active barriers and control interfaces.

These are IECEX certified components with an EPL Gc or higher and can therefore be installed in Zone 2, but often require additional enclosure for wiring together with other components, the guarantee of an IP rating and mechanical protection.The panels are thus built with increased safety enclosures. Those with EPL Gb are widely used on the market, even if the application in question could be compliant with systems with an EPL Gc degree of protection .The IECEX certificate for enclosures with components suitable for Zone 2 to which the switchboard refers indicates:

- the certificates of the admitted components

- the specific markings

- the specific conditions of use which will reflect those of the installed components.

A certificate that lists the component to be used implies that the dissipated power has been evaluated and that the temperature class and maximum surface temperature shown on the nameplate are actually those of the assembly thus created.Furthermore, the specific conditions of use of the component have been considered and the cable entry systems have been evaluated. With regard to the latter, we recall the exemption for cable glands, caps and threaded adapters which do not need to be present in the list of components.[3]

Figure 2: Example of an HMI mounted on the door of a stainless steel increased safety enclosure

Conclusions

Even for installations in Zone 2, what we have already highlighted in the previous article applies: the list of components in the certificate or in the use and maintenance manual is the attestation that the installation of a certain certified component has been assessed by the notified body.This requirement may be more difficult to understand than for a Zone 1 construction where the general safety level is higher and the certification costs are clearer.

[1] the reference is not to the Ex-ec increased security cases because the Ex-eb ones are widespread on the market

[2] the reference is to the IECEX scheme since according to the ATEX directive for category 3 equipment suitable for use in Zone 2 it is sufficient to create and store the technical file in the company, without involving a notified body – Article 13 (c) ATEX Directive 2014/34/EU

[3] The IECEX commission expressed its opinion on this topic with the decision ExTAG-DS-2012-008 sheet is freely available at https://www.iecex.com/members-area/extag-decision-sheets/

[4] HMIs are control panel screens, which act as a human-machine interface, the point of contact between a human operator and a machine. Their function is to monitor, control and interact.