Methods of protection in grain silos

As we explained in the previous newsletter of June, the grain silos are a store or a place outside or inside a building, in which are...

As we explained in the previous newsletter of June, the grain silos are a store or a place outside or inside a building, in which are stored food industry products, such as wheat, corn, rice or other similar products.

We saw that dusts in suspension can create potentially explosive clouds.

Therefore, all electrical and mechanical equipment must be designed, manufactured and maintained in accordance with the specific standards for explosion protection to avoid triggers.

Equipment classification

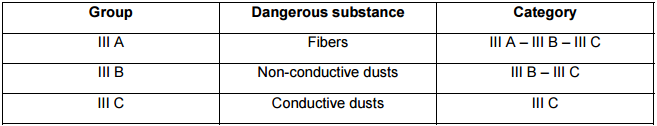

Recently, the Standard EN 60079-0 introduced the Group III for the classification of dusts that may form potentially explosive places. The table below shows the categories and the groups of equipment that can be used.

Equally to what happens for gases, the equipment manufactured for the most dangerous groups, can also be used for the inferior groups. Equipment suitable for the Group III C can, therefore, be used for all applications, while a device built for the Group III A, can never be used for a Group III B and III C.

Methods of protection for dusts

Once upon a time, there wasn’t a real division of the methods of protection for gases and dusts. The danger of explosion caused by dust clouds was understated respect to gas, vapors and mists ones. Therefore, the same methods of protection for Gases were used for dusts. Today, with the evolution of rules, we have defined the equipment that are designed specifically for environments with danger of explosion due to the presence of dust. While for gases is applied the principle that it’s impossible to prevent their penetration inside an enclosure, on the contrary, for dusts, the protection is based on the principle of prevent the dusts to penetrate into the enclosure in which the equipment that could sparkle are. The two basic principles of protection are:

- segregation

- prevention.

Compared to gases, therefore, lacks the principle of "containment". In the following table you can find the types of protection that can be used.

Choice of the method of protection

To select the right method of protection there’s no fixed rules. Manufacturers build equipment to suit every situation. The parameters of choice concern: the respect of rules for the choice of material depending on the type of area, where the equipment will be installed, the facility of installation, and, especially, the ease of maintenance. As we know, we have to choose the equipment, not only based on the initial cost, but considering the total cost for the entire period of its useful life. An equipment that requires less maintenance will be definitely preferable.

The explosion protection Ex t ... will be adequate for most applications in an industry electrical plant, such as what we can found near a silo. The pressurization has very high costs of conduction (the maintenance of internal overpressure provides a continuous use of energy for the pumping of air or inert gas), while the encapsulation is applied only to equipment that, once exhausted its life cycle, must be replaced.

Regarding the intrinsic safety, the powers involved are so low that the use is appropriate to the instrumentation and control of the process.

Marking

Nowadays, with all the existing regulations, one of the problems for the recognition of the material is given by the markings. An equipment suitable for the use in areas with danger of explosion due to the presence of dust, just as a silo, will have a marking like this:

- CE marking

- Number of the Notified Body. Eg: CESI

- EX marking

- Group II (for surface)

- ATEX Category (1, 2 or 3)

- Letter "D" for dust (Dust)

- Protection. Eg: Ex ta III A

- Temperature class. Eg: T6

- Certificate number: Eg: CESI 13 ATEX 123 X

Obviously, the equipment must be provided with the certificate of conformity issued by the certification body. Today, unfortunately, are put on the market products which are not always conform. Furthermore, the regulations evolution makes difficult to be sure that products conform to current standards.

The more serious manufacturer, therefore, are adopting identification systems (such as holograms that Cortem Group apply to equipment) that can be controlled in real time by visiting the manufacturer's website.