The EPL, the subgroup and the temperature class of the equipment

The installer must have clear and defined the information relating to the level of protection guaranteed against the risk of explosion regardless of the function of the device. This information can be found in the marking of the device and it is completed with the instructions for use.

by Andrea Battauz, R&D Project Engineer of Cortem Group

Introduction

Among the various areas of application of the ATEX directive, the most widespread is the one concerning surface systems with the risk of the presence of an explosive atmosphere due to a mixture of air and flammable substances in the form of GAS or vapor. [1]

In this sector, installers and designers often ask themselves questions relating to the choice of the right electrical appliances to be installed on the plant site.In the first in-depth study "The zones of the plant, the groups and the temperature classes of Gases" we saw that this choice begins with the characterisation of the site through the division into zones and the evaluation of the gases present in terms of gas group and class of gas temperature.

The time has come, therefore, to turn our interest to the characterization of the equipment. As for the installation site, this is a matter of deducing general methods and then classifying very different situations. The term equipment, in fact, can be understood as: control panels, electric motors, cable glands, sensors or still other devices, different in form and function.

The installer must have clear and defined the information relating to the level of protection guaranteed against the risk of explosion regardless of the function of the device. This information can be found in the marking of the device and it is completed with the instructions for use. Regarding the risk of explosion, the marking includes the requirements of the CE marking "... followed by the specific explosion protection mark, the symbols of the group and category of equipment." [2].

The marking

Often the marking is placed inside the product identification plate, other times, however, it is stamped or even engraved on the material itself. In any case, it must be visible and easy to use by the installer.

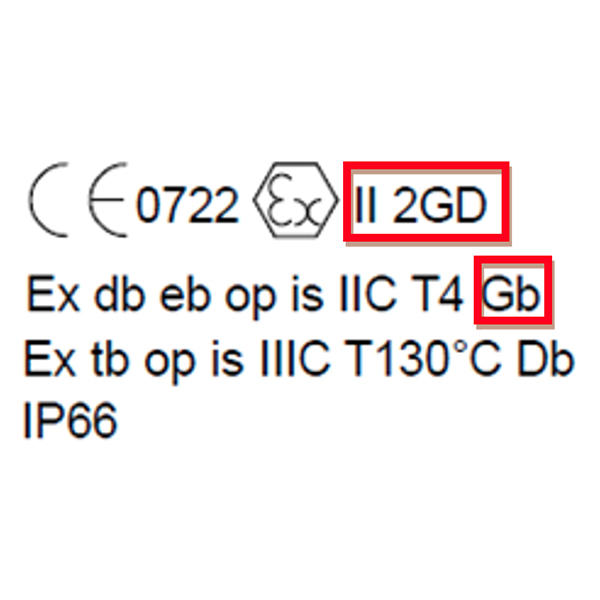

Figure 1: An example of a nameplate of Atex XLFE-LIB series signaling lighting fixture and relative detail

The plate contains a lot of information, from the manufacturer's address to the electrical parameters of nominal operation, up to the information relevant to the Atex.

Figure 2: Detail of the information relating to the Atex on the plate

EPL (Equipment protection level)

We focus now on those parts of the marking that give us an indication of the possible installation area of the device.

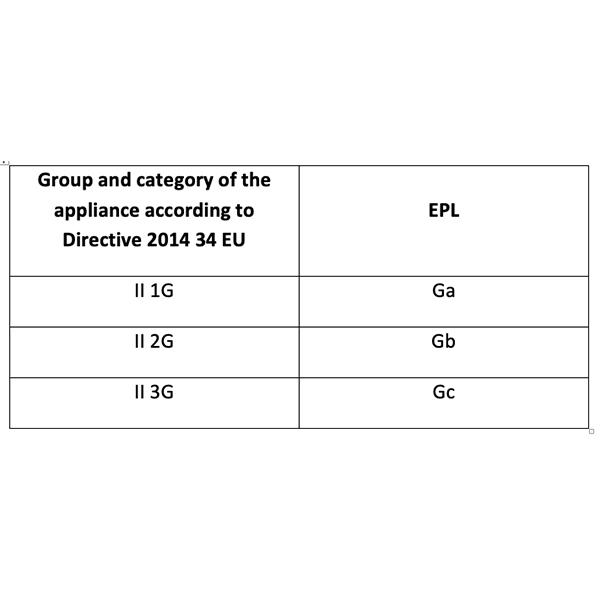

The Atex directive refers to the group and category of the equipment (in the Figure 3 the II 2GD, or II 2G considering only GAS). In addition, the harmonized legislation, first at an international level and then at a European level, has introduced the concept of EPLs, the "protection level" of the device for more than a decade. In the documents that introduced this concept, it was stated that it was useful to identify and mark all products based on their intrinsic ignition risk. [4]

We therefore have a redundancy in the Atex marking, whose meaning is understood if we consider the scope of the international IECEx standard where the first line of the marking (that of the CE mark) is absent.

The EPL, once identified in the marking, as we see from figure 3, facilitates the reading by the installer. In the following we will proceed by referring to the EPL of the equipment instead of using the concepts of Group and Category. This is to follow a more modern approach that cannot give rise to misunderstandings.

In the Table 1 the correspondence between Group and category of the appliance and EPL [3]

Subgroup and temperature class of the equipment

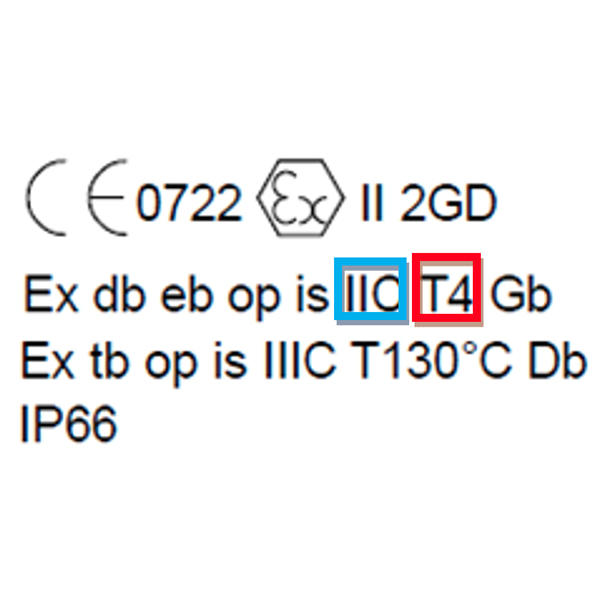

Now let's highlight those parts of the marking that give us an indication of the subgroup and the temperature class of the equipment. (Figure 4).

We focus on the first line below the CE marking which describes the type of hazard protection of atmospheres formed by gas or vapour.

Having limited this article to the case of places other than mines with the possible presence of grisou and potentially explosive atmospheres due to gas or vapors, the appliances will belong to group II which is divided into three subgroups of the appliance: IIA IIB IIC.

The subgroup of the device is indicated in the blue box, in some cases the equipment may report group II without further specifications, in this case it is equivalent to the IIC.The temperature class of the equipment is contained in the red box.The subgroup of the equipment and its temperature class are related to the protection method used to reach a specific EPL which is often reflected in clearly visible construction details.

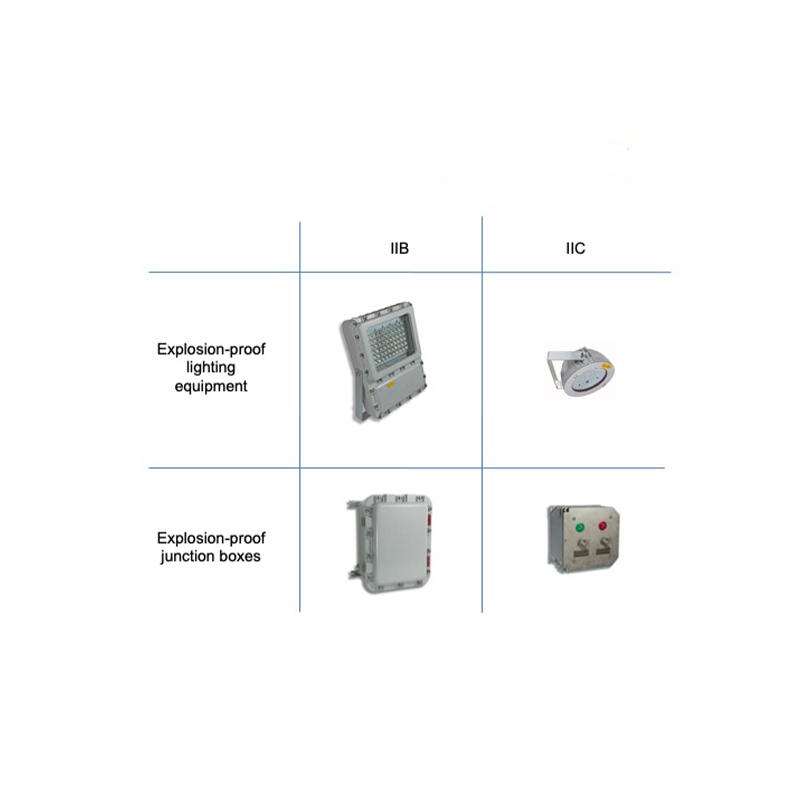

Figure 5: Examples of equipment with subgroups IIB and IIC made with the 'Ex db' protection method

Conclusions

In conclusion, we have seen how it is possible to extract the details of the EPL, the group/ subgroup and the temperature class of the equipment reading the marking.

_______________________________________________________________________________________

Reference standards and bibliography

[1] DIRECTIVE 2014 34 EU - ANNEX 1

The ATEX 2014 34 EU directive makes a first distinction between equipment for mining plants and equipment for surface plants. In the latter area, it then divides explosive atmospheres due to flammable gases, vapors, or mists from those due to dust. In the article we do not talk about "dusts" as they are excluded from the application of CEI EN 60079-14.

[2] DIRECTIVE 2014 34 EU Article 16 Paragraph 4

[3] extracted from Table 5.4-1 of CEI 31-108: 2016-11

[4] committee draft 31/763/CD IEC 60079-0 Ed. 6.0