Do you know LEDs may be damaged if in contact with particular chemicals?

During the assembly phases of lighting fixtures, different chemical components such as glues, conformal coating, grease and gaskets are...

During the assembly phases of lighting fixtures, different chemical components such as glues, conformal coating, grease and gaskets are used, which may contain volatile organic compounds (VOCs) that may pollute and damage LEDs, affecting their performance and reducing the lifetime of the product.

Therefore, testing the materials used in the assembly before the production is important, due to avoid unexpected problems on lighting fixtures already operative.

1. TheTest

For this reason, Cortem Group completed a test to evaluate the performance of CREE XT-E LEDs in presence of polluting atmospheres, according to the scheme n. CLD-AP63 Rev 5c published by CREE, relating to chemical compatibility.

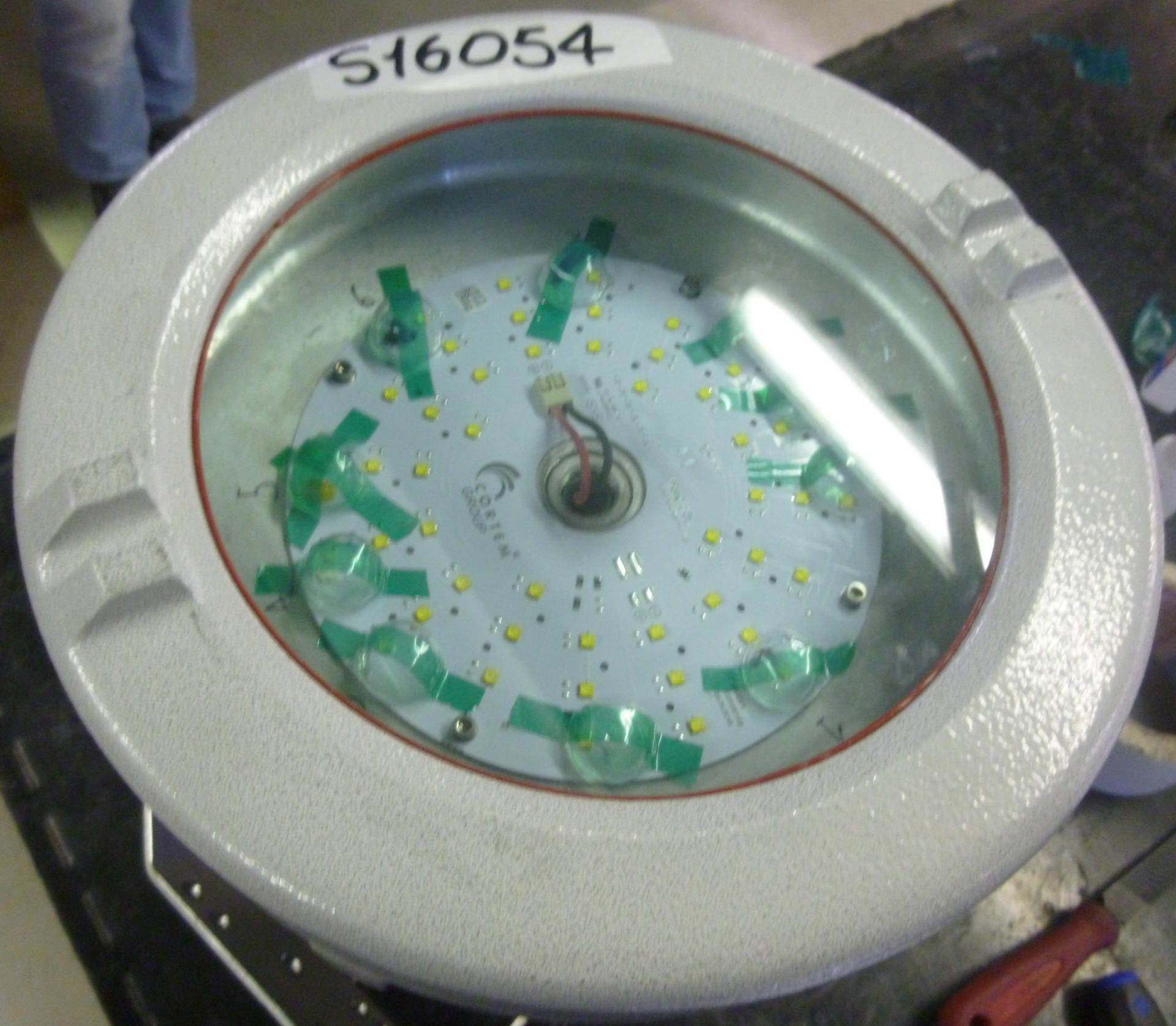

The test, made on a LED card installed into an EWL-801 series lighting fixture, last 3.000 hours (2.000h at ambient temperature + 1.000h in climatic room at +55C°).

In order to create an environment with high polluting probability, semi spherical glass domes were put on some LEDs of the card, in which potentially harmful substances were inserted.

2. The test result

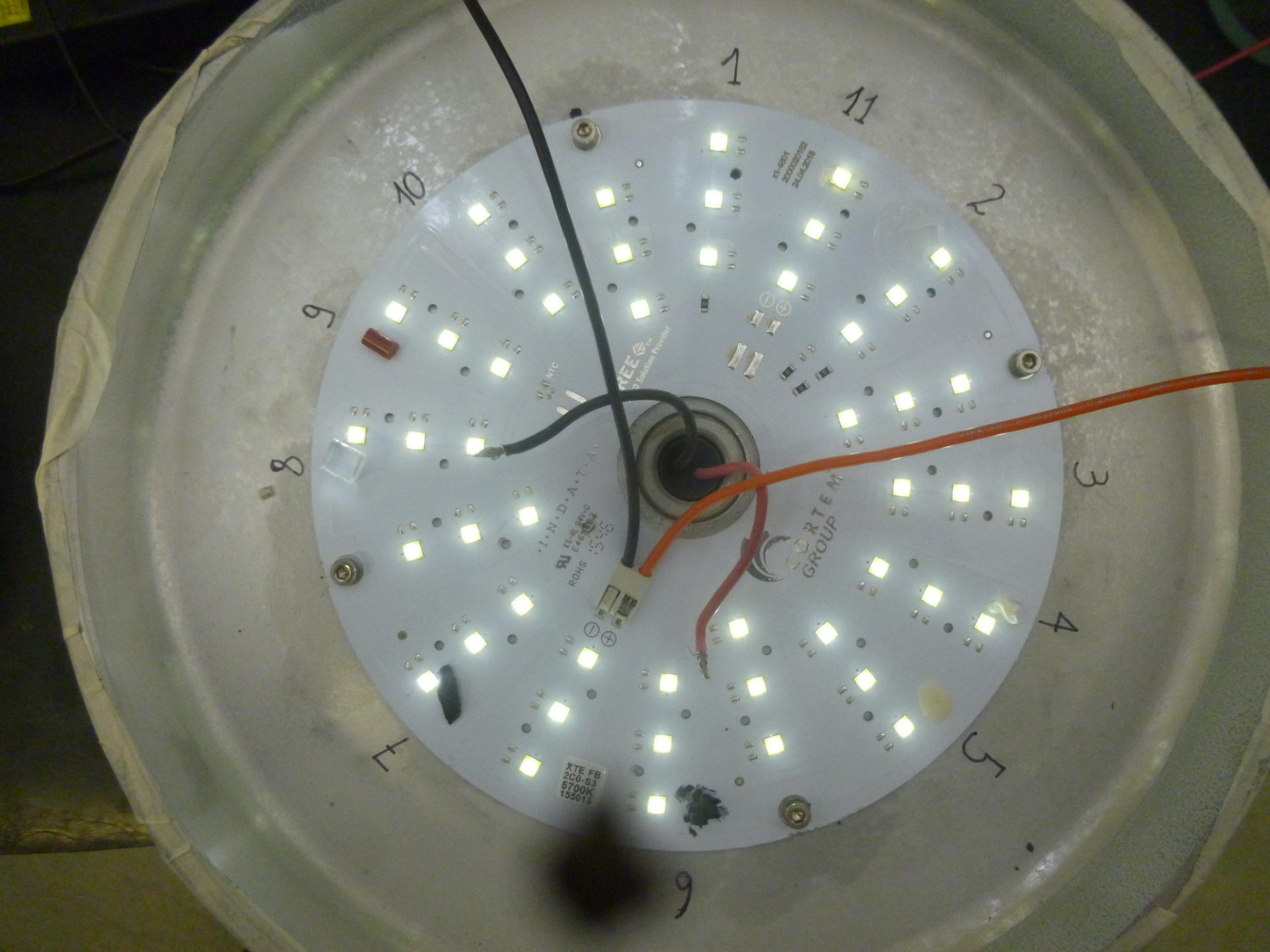

All chemicals used by Cortem Group for the assembly of lighting fixtures were tested in the ways described above. At the end of the test, the LED card has been evaluated analyzing:

- the colouring of the chip’s surface with card off, so as to identify if possible alterations happened;

- the luminous flux, to verify if a reduction due to a degradation of the component occurred.

For the final evaluation, the card was fed at the minimum ignition current so as to make visible if possible changes happened.

Both checks gave positive result for all the LEDs, thus confirming the compatibility of materials used by Cortem Group for the construction of its own lighting fixtures.

Cortem Group, thanks to its own Research and Development laboratory, recognized by Friuli Venezia Giulia Region as a “High Qualified Structure” in the field of materials analysis, with specific reference to explosion proof equipment, will keep constantly updated these reports based on the types of LEDs and production materials used. Therefore, customers are invited to carefully evaluate also this aspect while choosing a LED product addressed to areas with danger of explosion.