Explosion-protection in biogas plants

In modern biogas plants, biodegradable organic substrates are fermented such as grass, straw, slurry, manure, biodegradable waste,...

In modern biogas plants, biodegradable organic substrates are fermented such as grass, straw, slurry, manure, biodegradable waste, residues of food production, food scraps and grease. For this reason, airtight containers are filled with organic materials. In this environment, in absence of oxygen and with organic components in fermentation, the bacteria produce biogas. The biogas obtained is used to produce electricity and heat.

Type of plant

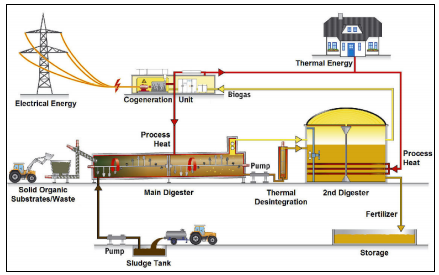

Biogas plants (see the scheme below) are composed of a primary mixing tank, possibly a sanitizing tank, one or more heated digesters, a final storage tank and, if necessary, a secondary digester. Once the biogas is produced, this must be handled and stored before to be reused. The co-generator is composed of a gas engine with a heat exchanger and a generator. The generator, on the basis of the biogas energy content, generates electric power, with an efficiency of about 30%, and heat with an output of about 60%. The electricity is fed into the network. The heat serves, partly, to the heating of the digester while the excess heat can be used, for example, for heating dwellings, agricultural structures or other production plants.

Danger of explosion

In a biogas plant there’s a constant presence of explosive atmosphere, in particular, in the area of the gas tanks and the digesters. So, these plants are to be classified as hazardous areas. Currently, ATEX Directive 94/9/EC and ATEX Directive 99/92/EC, become the point of reference with regard to equipment and protective systems addressed to explosive atmospheres. The reference standard for these types of plants is the UNI EN 1127-1 "Explosive atmospheres - Explosion prevention and explosion protection - Part 1: Basic concepts and methodology", in which are differed thirteen sources of ignition.

It’s a general law of protection that considers all the possible sources of ignition and, in particular, in this case, the protection against lightning. All these facilities are located in isolated open countryside and, therefore, are subject to the risk of lightning strikes.

Standard

As always in these cases, the employer has the obligation to detect and assess all the risk factors of production places with danger of explosion. The dangerous environments with explosive atmosphere must be divided into zones, using the EN 60079-10-1 standard for gases and the EN 60079-10-2 standard for dusts.

Depending on the results of the risk assessment, the definition of areas with danger of explosion must be described in a document for the protection against the danger of explosion.

Regarding the lightning protection, the standards to be used are EN 62305 series. All electrical devices located into classified zones, must meet the safety requirements and must be suitable for the type of classified area, as required by the ATEX 94/9/EC directive.