Corrosion issues and the metals used in equipment for potentially explosive atmospheres

Although corrosion is not a primary focus of the ATEX Directive, it remains a critical factor for the safety and, over time, this has led to the widespread adoption of aluminium–silicon alloys and stainless steels as the materials of choice for manufacturers operating in this highly demanding industrial sector.

by Andrea Battauz, R&D Project Engineer of Cortem Group

Premise

Many industrial plants operating in areas with a risk of explosive atmospheres (ATEX) are installed outdoors, often in regions exposed to extreme temperature ranges — from –60 °C up to +60 °C — such as deserts or arctic environments.In these conditions, temperature fluctuations, humidity, and proximity to the sea make corrosion resistance a key factor in ensuring the long-term reliability of equipment.

Materials and alloys used in ATEX-Certified equipment

The ATEX Directive mainly focuses on preventing ignition and containing potential explosions, while corrosion resistance is only marginally covered in the regulatory framework [1].Nevertheless, an overview of ATEX-certified equipment on the market shows that premium metals such as aluminium and stainless steel (particularly AISI 316 and AISI 316L) are commonly used.

This choice is driven by the need for long-term durability in harsh outdoor environments.

For example, aluminium alloys are widely adopted in flameproof enclosures thanks to their natural resistance to oxidation. When exposed to air, aluminium forms a thin protective oxide film that prevents further corrosion, unlike untreated carbon steel which readily forms rust [2].

Until the 1970s, cast iron was still widely used for enclosure casting because it was easy to process and suitable for mass production.Being a ferrous material, it required cadmium plating to avoid oxidation — a process later abandoned due to the toxicity and carcinogenicity of cadmium.With the development of aluminium casting technologies, cast iron was progressively phased out.

Today, aluminium–silicon alloys are the preferred choice for manufacturing flameproof enclosures. These alloys offer better corrosion resistance than aluminium–copper alloys, which are more typical in general industrial applications.While copper increases mechanical strength, it reduces resistance to saltwater and humid environments.

For this reason, the term “Copper-free aluminium alloys” is often used to describe aluminium–silicon alloys with low copper content (below 0.4%) — not completely copper-free, but optimized for corrosion resistance in challenging environments.

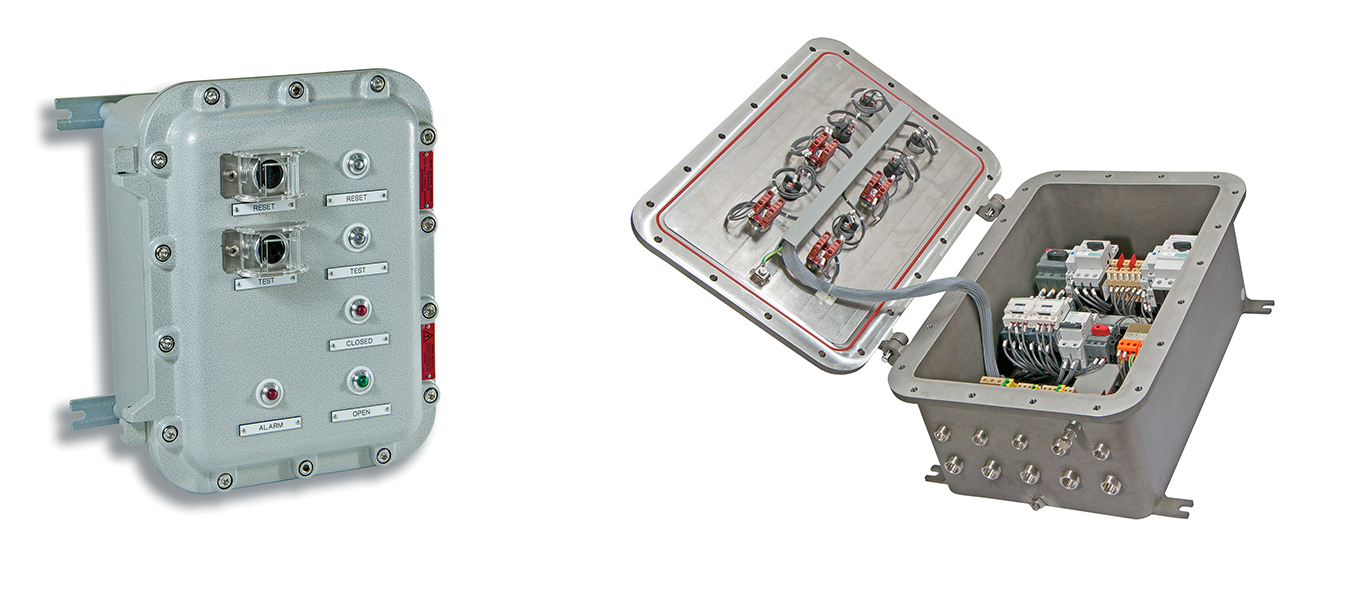

EJB series aluminum alloy and EJBX series stainless steel enclosures

Conclusion

Although corrosion is not a primary focus of the ATEX Directive, which mainly regulates explosion-related hazards such as impact-induced spark generation [3], it remains a critical factor for the safety, performance, and lifecycle of ATEX-certified equipment.

Over time, this has led to the widespread adoption of aluminium–silicon alloys and stainless steels as the materials of choice for manufacturers operating in this highly demanding industrial sector.

References

[1] Relevant guidance on corrosion can be found in Annex GB of CEI 31-108, ISO 12944, and IEC 61892-6.

[2] When exposed to air, aluminium oxidizes immediately, forming a thin (approximately 2–5 μm) layer of aluminium oxide (Al₂O₃) that protects the base material.

[3] Certain alloying elements are restricted above specific limits, and even aluminium alloys are excluded from Group I (mining) equipment due to the risk of friction-induced sparks.