The matching between the equipment and the installation site

Application of some simple rules to make a first match between the equipment and the installation site based on EPL, gas group and temperature class of the equipment.

by Andrea Battauz, R&D Project Engineer of Cortem Group

Introduction

Among the various areas of application of the ATEX directive, the most widespread is the one concerning surface systems with the risk of the presence of an explosive atmosphere due to a mixture of air and flammable substances in the form of GAS or vapor. [1]

In this sector, installers and designers often ask themselves questions relating to the choice of the right electrical appliances to be installed on the plant site.

In the first in-depth study "The zones of the plant, the groups and the temperature classes of Gases" we saw that this choice begins with the characterisation of the site through the division into zones and the evaluation of the gases present in terms of gas group and class of gas temperature.

In the second in-depth study “The EPL, the subgroup and the temperature class of the appliance” we have seen how it is possible to extract the details of the EPL, the group / subgroup of the appliance and the temperature class of the appliance from the reading of the marking.

We are therefore now able to apply some simple rules to make a first match based on EPL, gas group and temperature class of the equipment.The reference standard for the construction of systems is the CEI EN 60079-14 standard, national and European version of IEC 60079-14 "Design, choice and installation of electrical systems".

The matching between the equipment and the installation site

We report the rules for choosing the equipment in an easy-to-read table form.

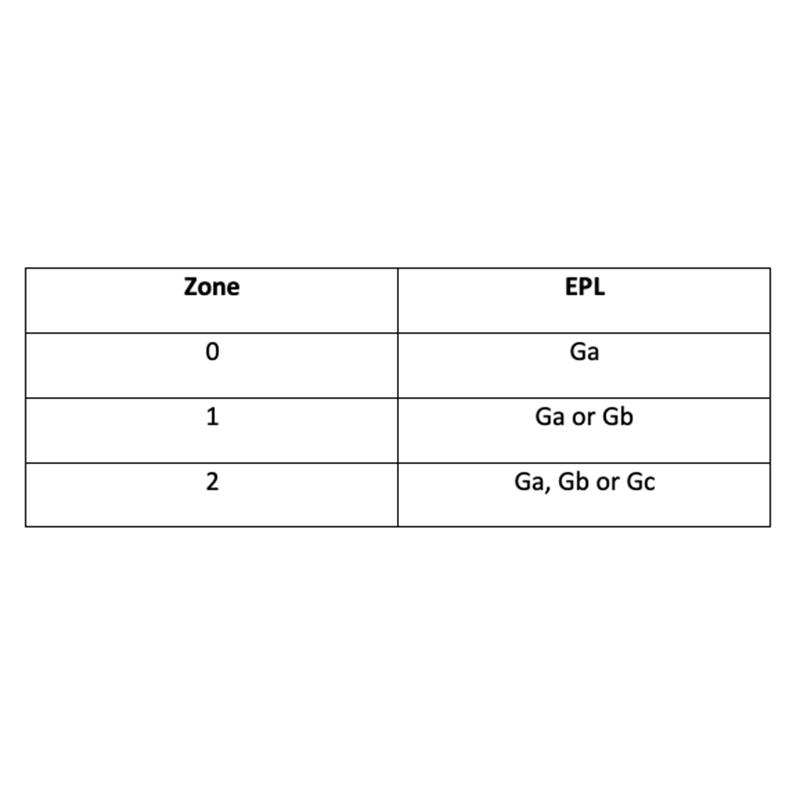

Table 1: correspondence between Group and category of the appliance and EPL [1]

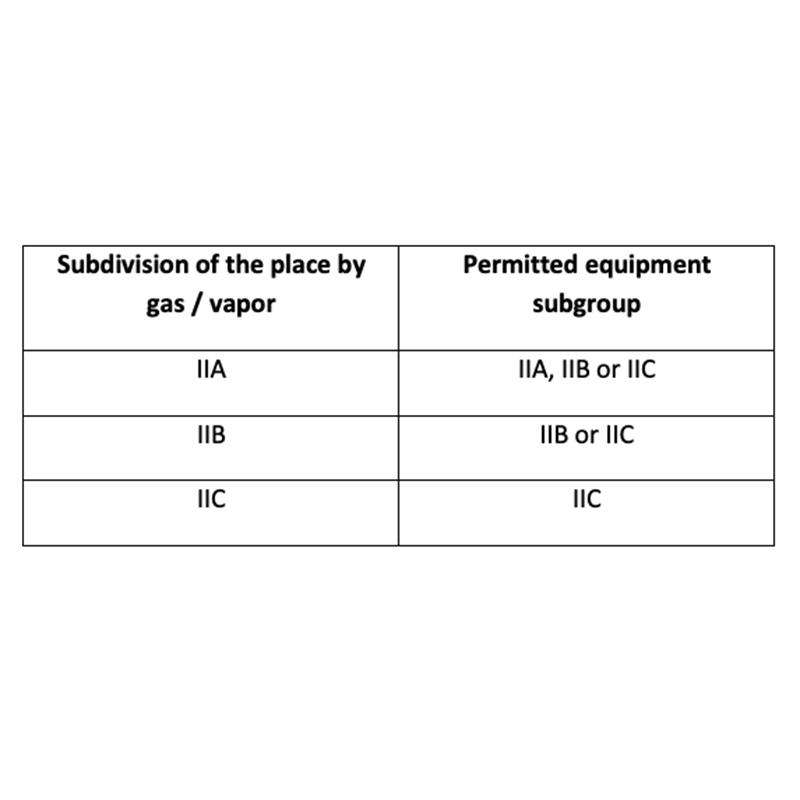

Table 2: correspondence between local gas group and equipment gas group [2]

For equipment with class II showed, it is to be understood as IIC

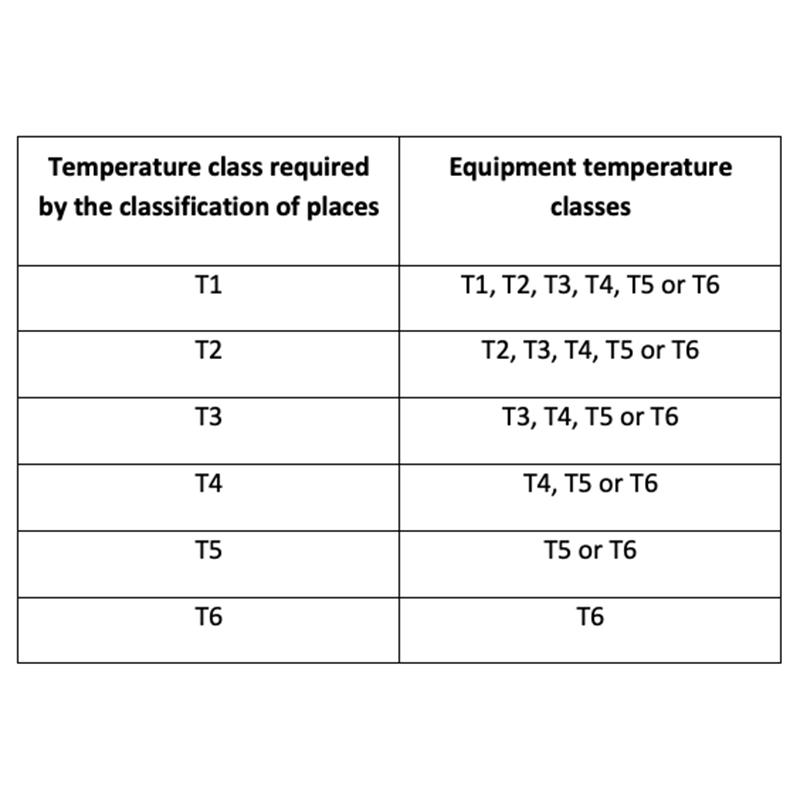

Table 3: correspondence between Temperature class required by the classification of places and acceptable temperature classes for the equipment [3]

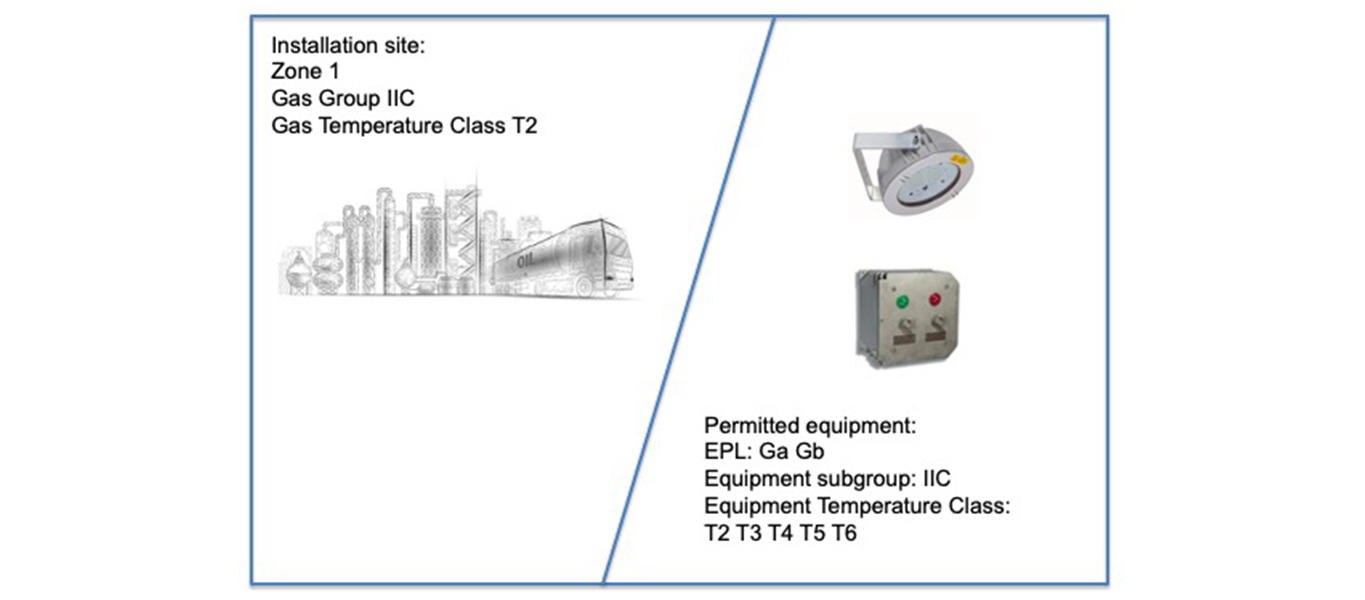

Figure 1 - Example of combination for Zone 1 IIC T2 plant site

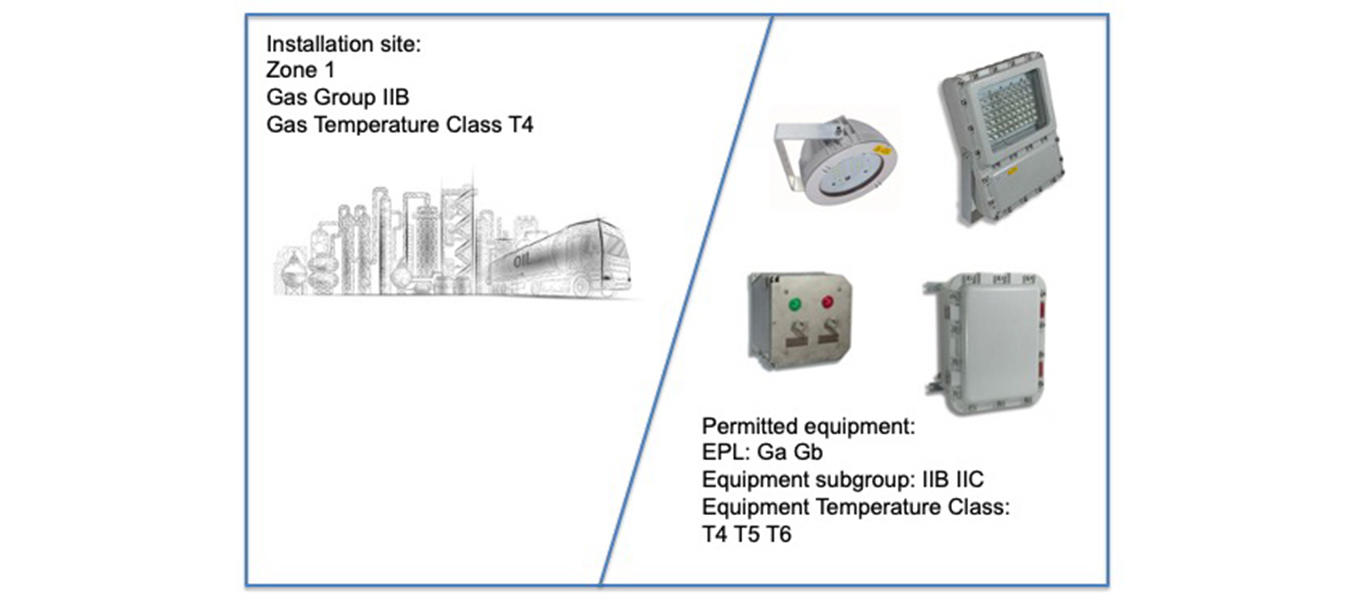

Figure 2 - Example of combination for Zone 1 IIB T4 plant site

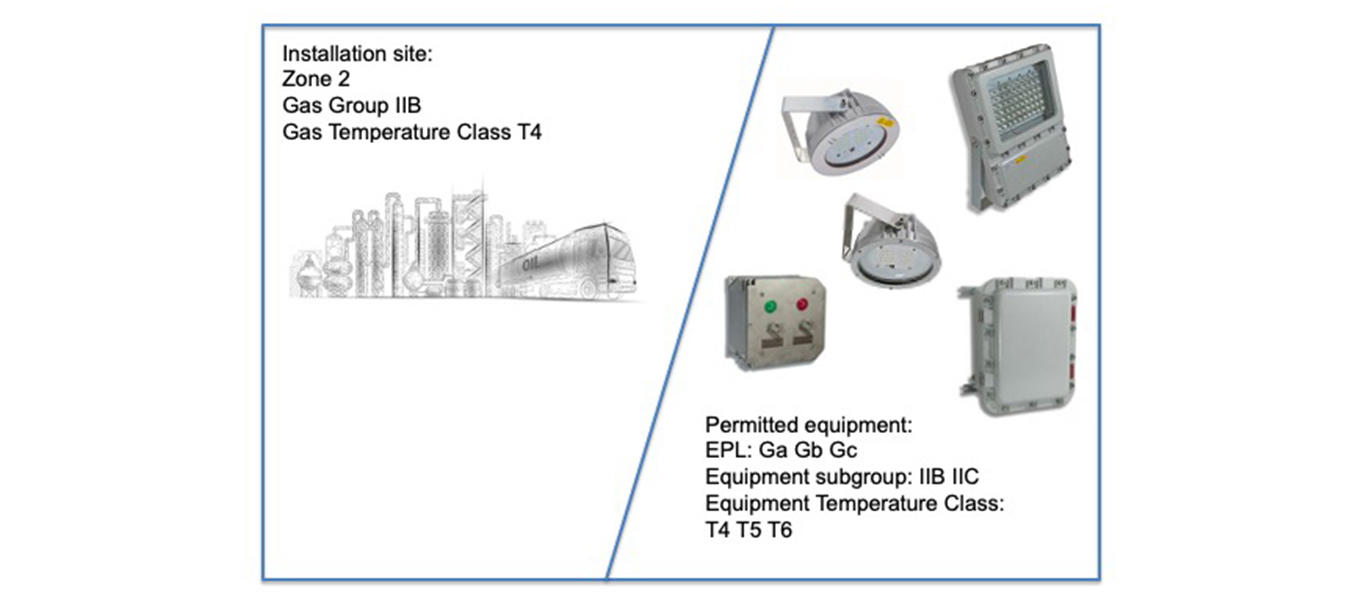

Figure 3 - Example of combination for Zone 2 IIB T4 plant site

Conclusions

We have seen how it is possible to make the right combination between the system site and the equipment by comparing the system zones with the equipment’s EPL, the gas group of the system with the subgroup of the equipment and the gas temperature class of the system with the temperature class of the equipment.

We started by clarifying what information was needed at the system level and compared it to the information on the equipment label.

Other parameters will then be taken into consideration, to be verified and validated based on the legislation. Just to name a few: the purely electrical parameters, the ambient temperature, the IP degree of the equipment, any radio frequency or ultrasound emissions etc.

What is certain is that those reviewed in this article are the most peculiar for the risk of explosion.

Reference standards and bibliography

[1] DIRECTIVE 2014 34 EU - ANNEX 1

The ATEX 2014 34 EU directive makes a first distinction between equipment for mining plants and equipment for surface plants. In the latter area, it then divides explosive atmospheres due to flammable gases, vapours, or mists from those due to dust. In the article we do not talk about "dusts" as they are excluded from the application of CEI EN 60079-14.[2] CEI EN 60079-14: 2014 TABLE 1

[3] CEI EN 60079-14: 2014 TABLE 3

[4] CEI EN 60079-14: 2014 TABLE 4