The use of LEDs in explosive atmospheres: evolution, foundation and advantage of an ever-changing technology

1. The "op is" safe optical radiation protection and the photo-biological risk As already mentioned in previous articles, the LED (Light...

1. The "op is" safe optical radiation protection and the photo-biological risk

As already mentioned in previous articles, the LED (Light Emitter Diode) has revolutionized the way of designing and manufacturing lighting equipment suitable for hazardous environments with presence of gas or dust. As consequence, the Ex manufacturers had to completely renew the construction range.

Cortem Group has been designing and manufacturing for several LED lighting equipment and it is constantly pursuing the search for new high performance LEDs, conforming to the new dictates in terms of security and in full respect of regulations specific to explosive atmospheres.

In this regard, Cortem Group obtained "op is" ATEX and IECx certification for some products and it is constantly upgrading its entire production range, in order to provide products that fully meet, in addition to the standards relevant to constructive concepts such as IEC/EN 60079-0; IEC/EN 60079-1; IEC/EN 60079-7; IEC/EN 60079-18; IEC/EN 60079-31, also in compliance with the specific features of the "op is" protection, in accordance with IEC/EN 60079-28 standard.

The "op is" protection standard describes the necessary requirements to prevent visual or infrared optical radiation from being the source of explosion in explosive atmospheres. This type of protection includes the entire optical system of the lighting fixture which, in order to ensure the non-production of sufficient energy to ignite an explosive atmosphere under normal or specific failure conditions, becomes essential for a proper alignment and compliance with relevant standards.

In 2006, the IEC adopted the guidelines of CIE S009/E-2002 and published the IEC 62471:2006 standard "Photobiological Safety of Lamps" with CIE. In 2008, the European version, EN 62471:2008 was issued. The standard provides the guidelines for the evaluation and control of photobiological risks arising from all electrically powered lighting fixtures, including LEDs, in the range from 200 nm to 3000 nm wavelengths.

The normative IEC/EN 62471, concerning the photobiological risk, states that light radiation can cause skin and eye damage. Not only LED light but any light source can cause damage. The legislation obligates the manufacturer to carry out laboratory tests and to place on the lighting fixture body, if such radiation is present, the relevant risk class, depending on the emission limits not to be exceeded, according to the tests defined in the standard.

With optical radiation

Without photobiological risk

The potential damage to the light radiation varies with the wavelength and the received quantity. The quantity is the result of the power for the exposure time. Intense radiation takes less time to cause damage respect to a lower intensity one. For example, if it is possible to be sunburned with a 1-hour exposure in August, it will serve 8 hours during a May day.

2. Cortem Group LED lighting fixtures and floodlights

After analysing what the LED market offers was offering us by comparing the production quality of each manufacturer, we have chosen products that could give us the appropriate functional guarantees about the very low "infant mortality" of LED and, therefore, we continued with the engineering of new lighting fixtures designed depending on application parameters guaranteed by the producers themselves. These parameters must be appropriate to the right temperature dissipation for an adequate and sustainable use in terms of the warranty for the customer.

The use of appropriate LED lighting fixtures allows to obtain numerous advantages. Consider that a discharge lamp of 400 W can be replaced with LEDs with a power of 160 W, with an energy saving of about 60%. Furthermore, current Cortem LED lighting fixtures, in addition to being not much more expensive to lighting fixtures for discharge lamps, are plenty amortized over time due to the lower costs of maintenance. The frequency of maintenance, in fact, decreased by 1.7 compared to the activity required for the re-establishment of a discharge lamps lighting fixtures. It’s well known that a discharge lamp has an average life ranging from 3.000 to 10.000 hours and then stops working, while LEDs have an average life of 50.000-70.000 hours and continues to work, even with lower light flux.

The use of LEDs in the new range of Cortem products allowed us to obtain T6, T5 or T4 temperature classes, depending on the type of floodlight, much lower than the temperature classes of the discharged models that have classes T2 or T3. They can therefore be installed in hazardous areas where, until now, it was unthinkable to install a floodlight.

One of the main problems encountered, in order to ensure the safety in the workplace, is to ensure an adequate level of illumination of the plants. In particular, the characteristics of electrical equipment installed in areas with danger of explosion are designed with even greater attention to get good illumination and reduction of risk conditions. About 80% of all our sensory impressions are of optical nature and they need of light as a vehicle of information. Good lighting, therefore, not only facilitates the vision and the recognition, but it greatly reduces the danger of accidents.

Devices that are installed in classified areas must therefore, in addition to explosion protection, ensure the correct luminous flux required for the execution of all work operations in safe conditions and must have other characteristics such as insensitivity to vibration, instant restrike voltage reset and reduced maintenance need to minimize the risks associated with the functionality of the equipment.

2.1 The Light Spectrum

The light spectrum of white LEDs of the latest generation, such as those used for the realization of our LED range, is about as close to sun light spectrum.

In the diagrams below, you can appreciate the differences between the spectrum of sunlight and of other light sources, such as fluorescent lamps, discharge lamps and white LEDs.

In our new-generation lighting fixtures, only Cree, Philips, Seoul and Citizen production LEDs have been selected, with maximum efficiency, in order to obtain the best light quality and maximum lm/W (lumen / watt) ratio.

All lighting fixtures have a CRI (Colour rendering index) > 70 and a standard light colour white 5700° K (for special needs, can be requested a different colour temperature).

2.2. The thermo-graphic survey

As we said in the introduction, the LED lighting fixtures must be designed and constructed specifically. The construction of bodies in aluminium alloy, designed with elements of heat dissipation, is the key to obtain an efficient and long lasting system. The housing of the feeder must be correctly calculated in terms of volume to allow easier heat dissipation.

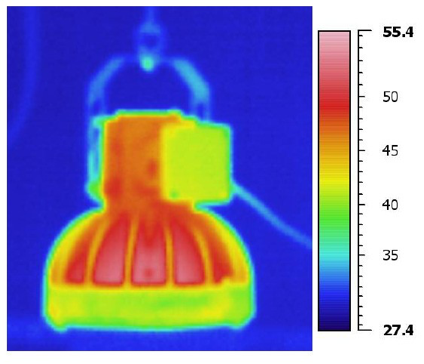

Thermo-graphic survey (referred to the EWL series lighting fixture)

After an initial transition period the lighting fixture reaches thermal stability. In this picture you can appreciate the thermo-graphic survey.

With an ambient temperature of 28°C (shown by the blue background colour), the Led lamp touches the hottest point at 56°C.

These thermal performances are the tangible proof of the high efficiency of the LED light source. It also reports the temperature distribution on the frets of a refined Thermal Management. For this reason, lighting fixtures are designed around the LED.

The finned body, made of aluminium alloy, acts as a heat sink for the LED plate mounted directly inside, on the body of the lighting fixture allowing it to dissipate more quickly and effectively the heating generated by the operation of the LEDs themselves.

The design of the lamp body, in addition to being functional to the duration of the system, has allowed obtaining equipment with high luminous efficiency in relation to the maximum surface temperature. This is a very important factor for the installation of lighting fixtures in places of danger, containing gas or powders at low ignition temperature.

3. The main advantages of LED technology

Safety is essential for workplaces and, especially in areas with potentially explosive atmospheres, the risks are very high. Any system, therefore, that allows to reduce the level of risk is always well accepted. Furthermore, if there are savings in money and energy, then the advantage is total.

We summarize here, in conclusion, the main advantages that presents the range of Cortem’s LED products:

- Energy saving with maximum efficiency, more light and less consumption.

- Longer life than conventional bulbs and, thus, reducing of maintenance costs.

- Savings of plant costs, lower costs to bring energy to the lamp.

- Directional light and superior quality allow a better identification of the colours of illuminated objects. Safety in the workplace.

- Use in lighting systems at low voltage (24Vdc).

- Resistance in the ON/OFF cycles.

- No Light Out for the security in the workplace.

- Resistance of the components to the electrical and mechanical stresses.

- Less weight, less volume, easier handling.

- Excellent heat dissipation for longer life of the LED.

- Possible electronic control of the light output (dimming).

- Respect for the environment, compliance with the standard anti-light pollution.

- Excellent performance in extreme climates.

- Immediate availability of the maximum light output power.

- Very low mortality of LEDs.

- Lower temperature classes.

- 'Ex de' method of protection allows the entry of the cable without realizing any conduit system with sealing.

- Possibility of replacing the LED plate with a more advanced technology (Future Proof).

- In the remote case of failure of one of the LEDs, the Ex safety remains unchanged.

- Multifunctional. From lighting fixtures to floodlight with the sole plate replacement.

- Guaranteed 50,000 hours (25° C ambient temperature).

- Suitable for classified areas as IIB and IIC.

- 100% recyclable.

- No flickering.

- Absence of hazardous substances such as the mercury for fluorescent lamps.