Criteria and responsibilities in electro-instrumental systems in classified areas

1. Introduction The constant and continuous technical evolution consequently leads to the need to update reference standards of everything...

1. Introduction

The constant and continuous technical evolution consequently leads to the need to update reference standards of everything concerning the installation, operation and maintenance of the electro-instrumental equipment suitable for installation and operation in environments with the presence of explosive gases or dusts.

For these reasons, it is essential that the designer, the manager and maintenance operator of such equipment must have all the regulatory tools always present and constantly updated, in order to correctly design and size the electro-instrumental equipment and then to keep them constantly efficient, respecting the protection of people and things.

2. The regulations covering the Ex field

The following list of the regulations describes the fundamental criteria to be adopted for the construction, installation and maintenance of electro-instrumental equipment. They are subdivided into national regulations (CEI EN), Community regulations (EN) and international standards (IEC). In addition, there are other regulations that are specifically intended for the destination country of such equipment and that are an integral part of or replace those mentioned above.

Considering that the origin of the rules belongs to the international ones, actually the communitarian and the national ones incorporate the international regulation with possible changes to adapt them to the national laws and/or the community directives. Therefore, we will list only the final part of the norm, omitting the prefix (CEI or EN or IEC):

• 60079-10-1: this is the standard that determines the classification criteria for hazardous areas in the presence of potentially explosive gases.

• 60079-10-2: this is the standard that determines the classification criteria for hazardous areas in the presence of potentially explosive dusts.

• 60079-14: this is the standard that dictates the criteria for the design, selection and installation of electrical systems in explosive atmospheres.

• 60079-0: this is the standard that defines the general requirements regarding the construction, testing and marking of the Ex equipment and components intended for use in environments with explosive atmospheres.

• 60079-1: this is the standard that determines the requirements for the construction and testing of protected equipment using explosion-proof enclosures "d".

• 60079-2: this is the standard that determines the criteria for the construction and verification of electrical constructions intended to be used in an explosive atmosphere due to the presence of gas, using the internal overpressure protection mode "p". This standard should be used in conjunction with the 60079-0 standard.

• 60079-5: this is the standard that determines the specific criteria for the construction, testing and marking of electrical equipment, parts of electrical equipment and Ex components in the type of "q" powder-filled protection, intended for use in atmospheres with explosive gases.

• 60079-6: this is the standard that determines the criteria for the design, construction, testing and marking of Ex equipment with liquid immersion "o" type of protection intended for use in explosive gas atmospheres.

• 60079-7: this is the standard that determines the criteria for the design, construction, testing and marking of electrical equipment and components with increased safety type "e" intended for use in explosive gas atmospheres.

• 60079-11: this is the standard that determines the criteria for the construction and testing of intrinsically safe "i" devices for use in an explosive atmosphere and for the associated equipment, which are intended for connection to intrinsically safe circuits. This type of protection is applicable to electrical equipment in which the electric circuits themselves are not able to cause an explosion in the surrounding explosive atmospheres. This standard is also applicable to electrical equipment or parts of electrical equipment located outside the explosive atmosphere or protected by another type of protection listed in 60079-0, where the intrinsic safety of electrical circuits in the explosive atmosphere may depend on the design and construction of such electrical equipment or parts thereof.

• 60079-13: this is the standard that determines the criteria for the design, construction, evaluation, verification and marking of the premises used to protect the equipment, through pressurization or artificial ventilation or both, as appropriate, when they are located in an explosive gas atmosphere or hazardous area with a combustible dust atmosphere with or without an internal source of flammable gases or vapors.

• 60079-15: this is the standard that determines the criteria for the construction, testing and marking of Group II electrical equipment with type of protection, "n" intended for use in explosive gas atmospheres. This standard applies to electrical equipment in which the rated voltage does not exceed 15 kV r.m.s. in alternating current or in direct current.

• 60079-18: this is the standard that determines the criteria for the construction, testing and marking of electrical equipment, parts of electrical equipment and Ex components with the type of encapsulation protection "m" intended for use in explosive gas atmospheres or in explosive powder atmospheres.

• 60079-25: this is the standard that determines the requirements for the construction and evaluation of intrinsically safe electrical systems, type of protection "i", intended for use, as a whole or in part, in areas where the use of group I, II or III equipment is required.

• 60079-26: this is the standard that determines the alternative requirements for the construction, testing and marking of electrical equipment that provide the level of protection of the equipment (EPL) Ga when it is not possible to apply single standardized protection types (for example Ex "ia", Ex "ma", Ex "da"). This standard also applies to equipment mounted on a boundary where different levels of equipment protection may be required.

• 60079-28: this is the standard that determines the requirements for the testing and marking of equipment emitting optical radiation intended for use in explosive atmospheres. It also covers equipment located outside the explosive atmosphere or protected by a type of protection listed in IEC 60079-0, but which generates optical radiation intended to enter an explosive atmosphere. It covers Groups I, II and III and EPL Ga, Gb, Gc, Da, Db, Dc, Ma and Mb.

• 60079-29-1: this is the standard that determines the requirements for construction, testing and performance and describes the test methods applicable to portable, transportable and fixed equipment for the detection and measurement of concentrations of flammable gases or vapors with air.

• 60079-29-2: this is the legislation that determines the selection, installation, safe use and maintenance of Group II electronically-controlled equipment intended for use in industrial and commercial safety applications and Group I equipment for underground coal mines for the detection and measurement of flammable gases that comply with the requirements of IEC 60079-29-1 or IEC 60079-29-4.

• 60079-29-4: this is the standard that determines the performance requirements of equipment for the detection and measurement of flammable gases or vapors in ambient air by measuring the spectral absorption of gases or vapors on extended optical paths, which vary from one meter to a few kilometers.

• 60079-30-1: this is the standard that determines the specifies general and testing requirements for electrical resistance trace heaters for application in explosive atmospheres with the exclusion of those for EPL Ga and Da. This standard covers trace heaters that comprise either factory or field (work-site) assembled units, and which may be series trace heaters, parallel trace heaters, trace heater pads or trace heater panels that have been assembled and/or terminated in accordance with the manufacturer’s instructions.

• 60079-31: this is the standard that determines the requirements for electrical equipment protected by enclosure and by the limitation of the surface temperature for use in atmospheres with explosive powders. Specifies the requirements for the design, construction and testing of Ex "t" electrical equipment. This standard does not apply to explosive powders, which do not require atmospheric oxygen for combustion or pyrophoric substances.

There are also a further series of standards aimed to the maintenance and repair of equipment such as:

• 60079-17: this standard applies to users and covers the factors directly related to the inspection and maintenance of electrical systems located only in dangerous areas, where the danger may be caused by gases, vapors, mists, dust or volatile flammable fibers.

• 60079-19: this is the standard that provides instructions, mainly of a technical nature, on the repair, overhaul, reclamation and modification of equipment designed for use in explosive atmospheres. It is not applicable to maintenance, except when the repair and overhaul cannot be dissociated from maintenance, nor does it provide advice on cable entry systems that may require renewal when the equipment is reinstalled. This regulation does not apply to the type of protection "m", "o" and "q".

The guide relevant to the definitions of who does and what can be done in the field of maintenance and/or repair interventions completes the series:

• OD 203: this operational document provides guidance on the ExMC accepted definitions of the terms ‘manufacturer’ used in the context of the IECEx System in relation to ‘trade agents’ and ‘local assemblers’ and it is published in two sections:

- SECTION 1 Issue of IECEx Certificates of Conformity covering a distributor or agent who does not actually manufacture the equipment.

- SECTION 2 Use of a Local Assembler for final assembly and dispatch of a product made from fully defined parts supplied by the manufacturer.

This Operational Document is intended to support the implementation of IECEx OD 009 and should be read in conjunction with the requirements defined in this document.

3. The current systems variants

Considering the above, it is clear that the duties of the designer first and of the maintenance technician then are of fundamental importance for the correct sizing and management throughout the life cycle of the plant where the electro-instrumental equipment will be installed.

Starting from 2015, the regulation 60079-14 has introduced a radical change on the plant concepts, in this case on the criterion of cables entry/exit from the electro-instrumental equipment.

In fact, while in the old version of this regulation, in the paragraph 10.4.2 "Choice of cable glands", prescriptions were given according to the volume and type of construction, in the new version these requirements have been completely changed.

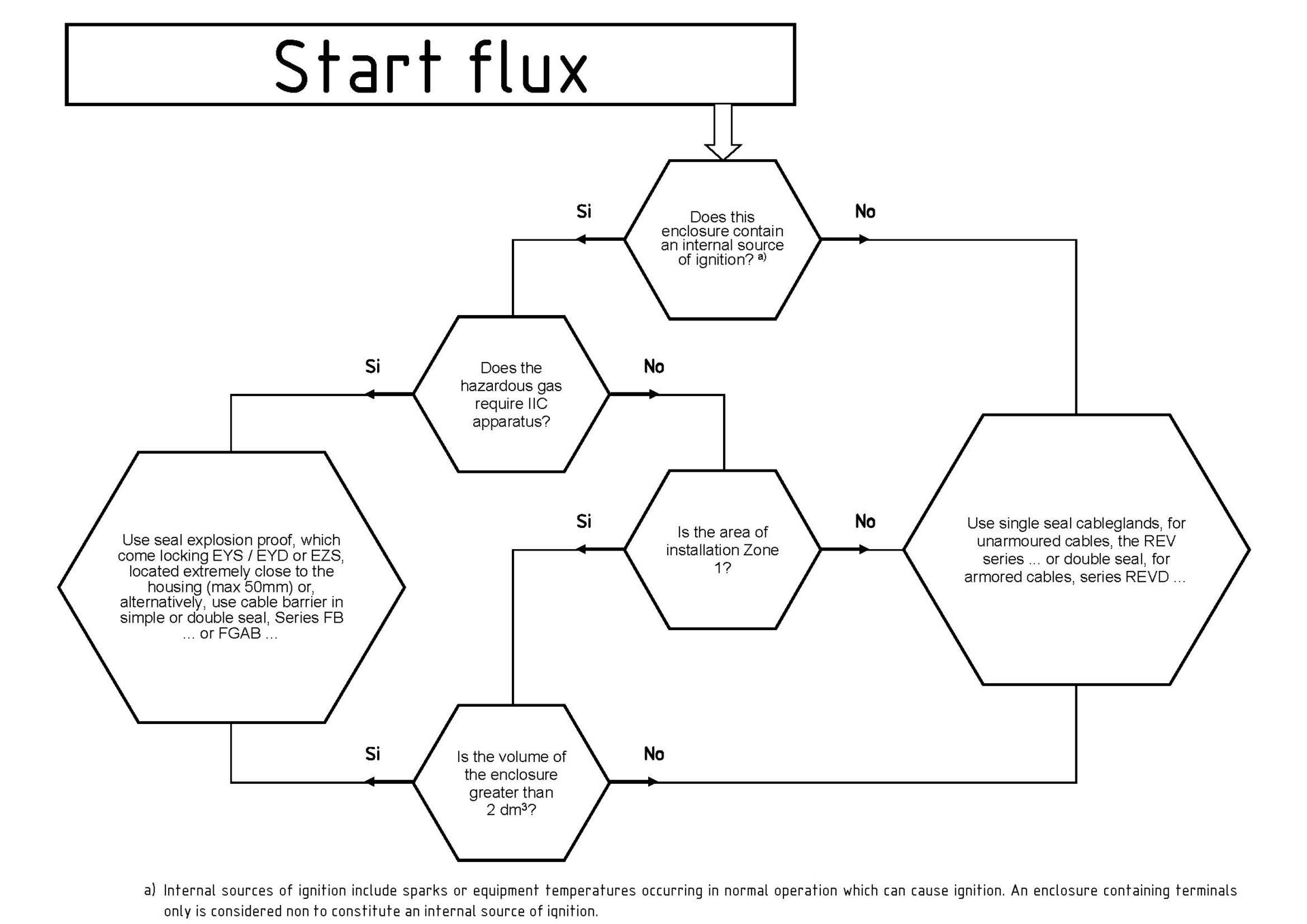

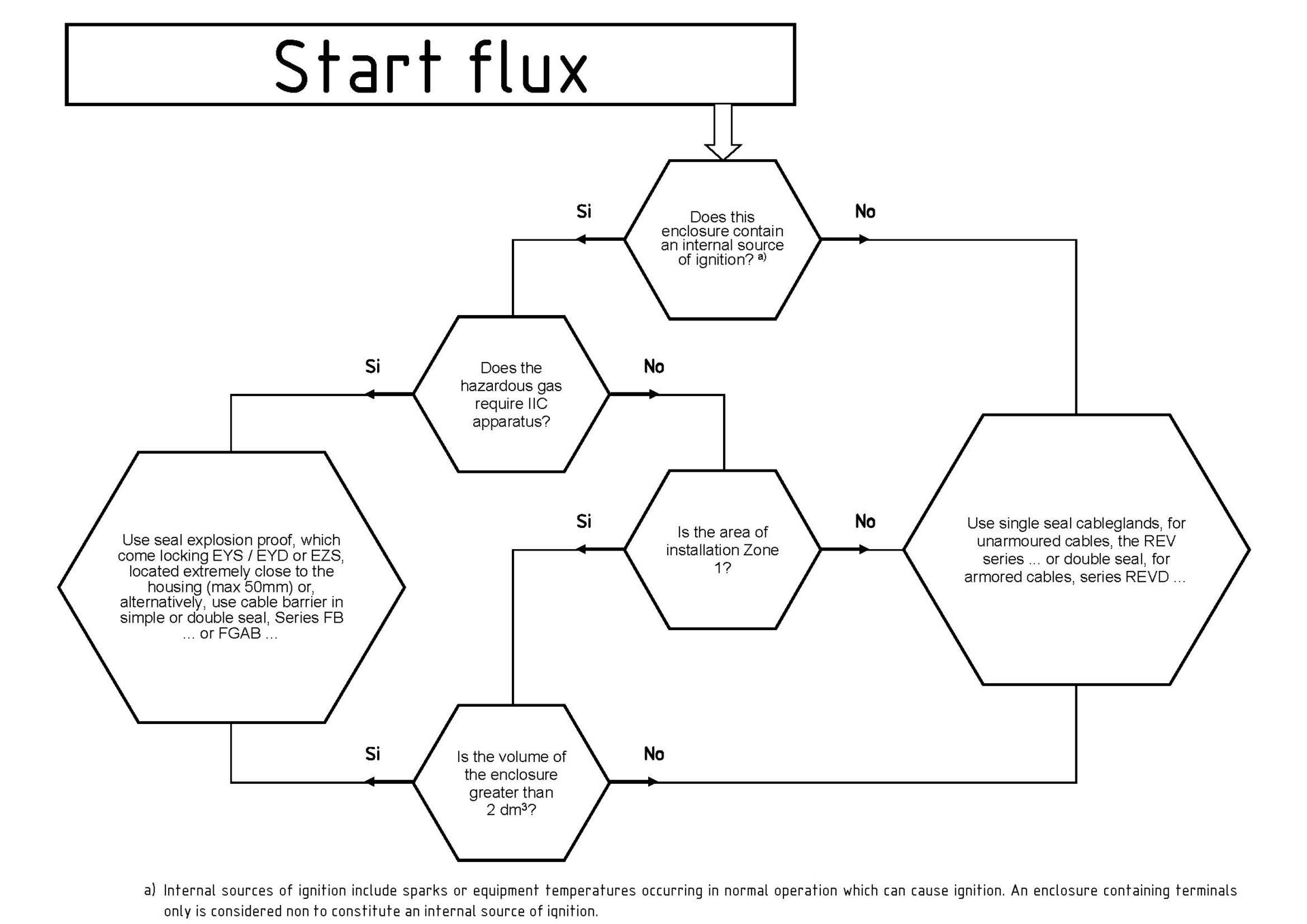

Old scheme, according to paragraph 10.4.2 of the old regulation 60079-14: 2010-02

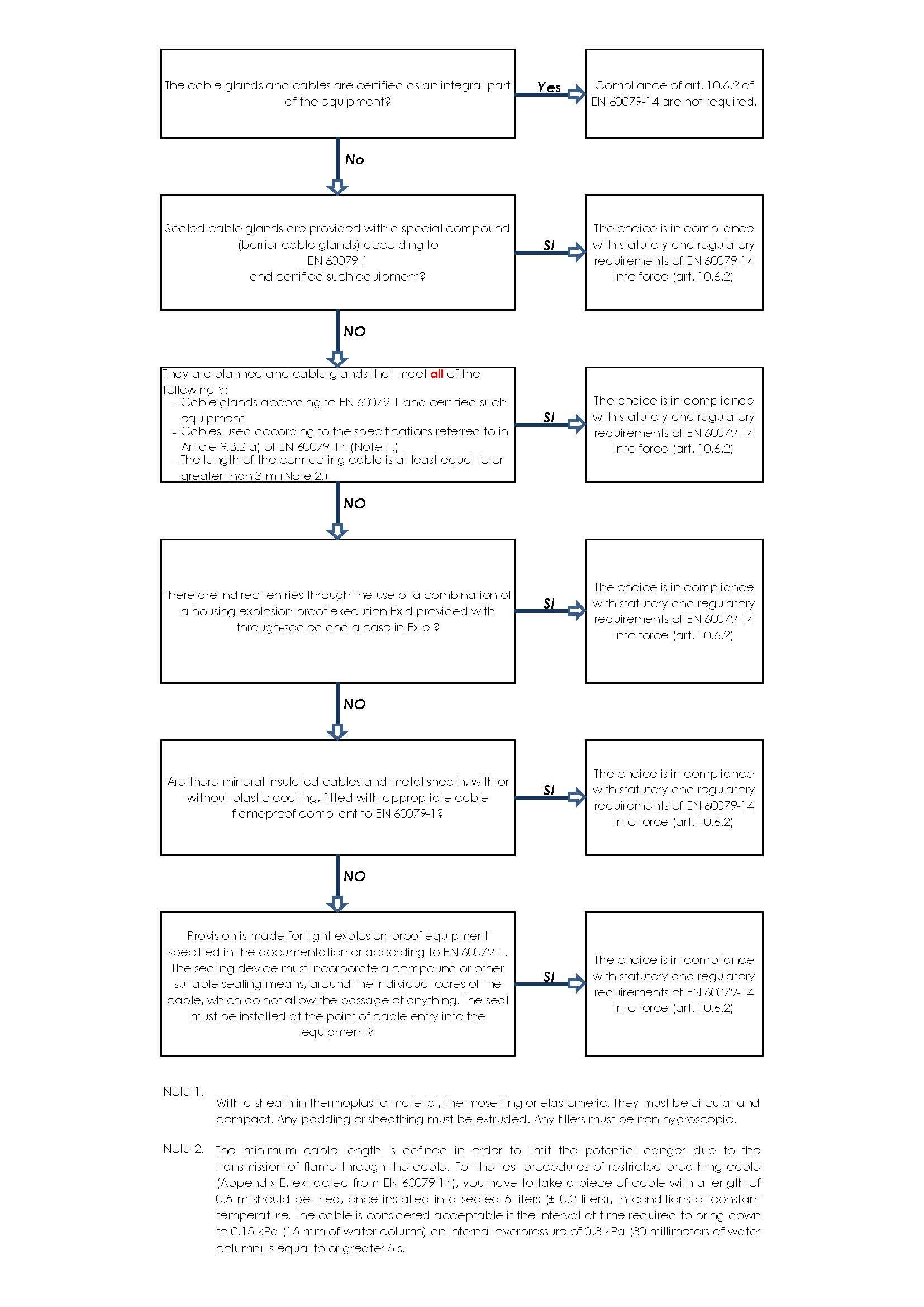

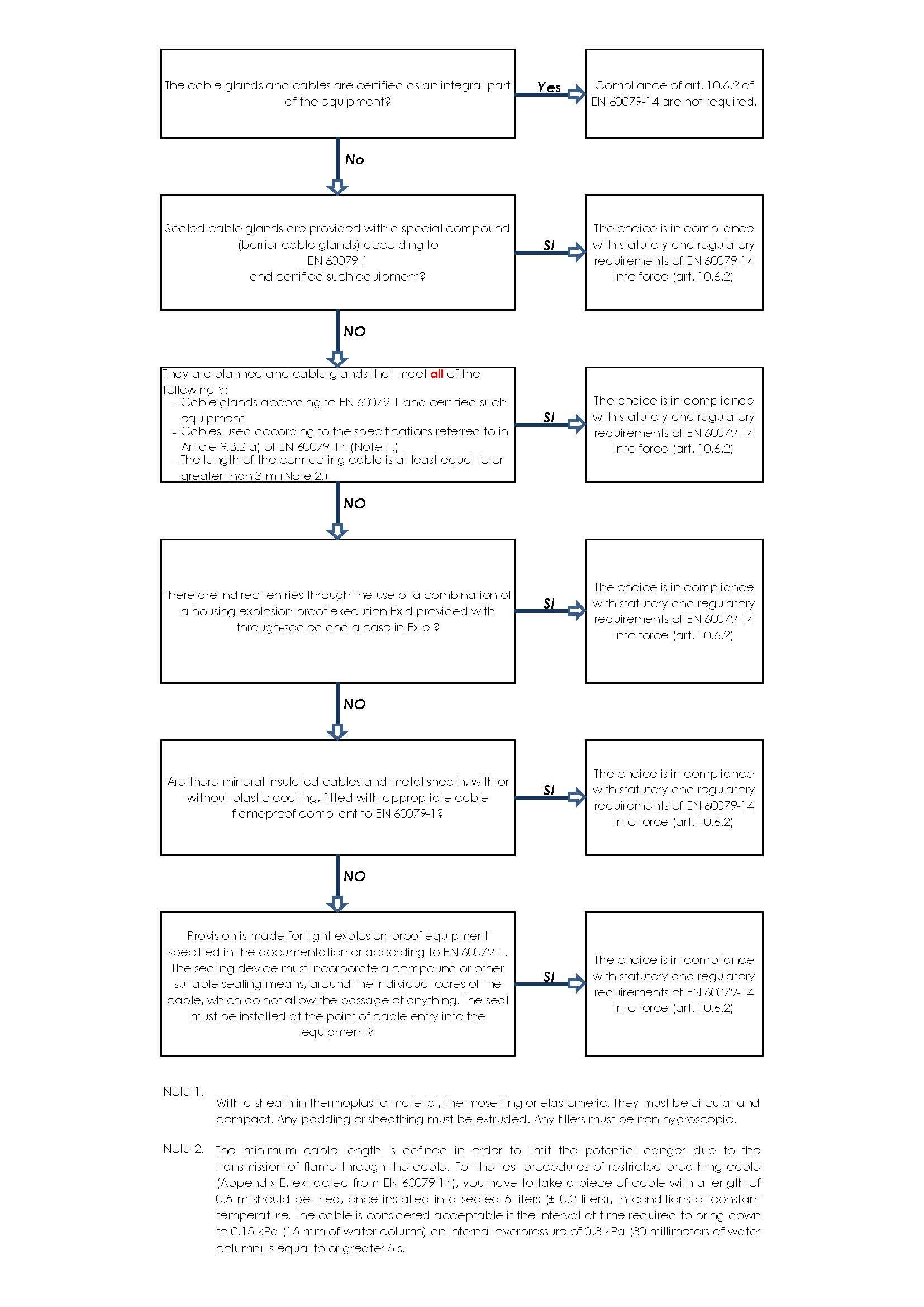

New scheme, in accordance with paragraph 10.6.2 of the new regulation 60079-14: 2015-04

As can be clearly seen, the volumetric limit no longer exists but the choice will depend on the type of system. In fact, if the leak test cannot be carried out, as specified in the Annex "E" of the standard, therefore not using "Barrier" cable glands with cable lengths exceeding 3 meters, only single or double seal cable glands should be installed, depending on the type of cable if non armoured or armoured, but strictly of the "Barrier" type, such as our "FB" series cables, for non armoured cables or "FGAB" for armored cables.

4. The responsibility of the designer

The designer is responsible for the correct selection of components, based on plant requirements and areas of use, in addition to the various environmental conditions. The choice of the equipment cannot be left to the manufacturer which only accept the designer's requests and takes care of the correct sizing, according to the design requirements such as temperature class, design temperature, type of installation and environmental conditions, in agreement to the requirements imposed by pertinent certifications.

5. The responsibility of the installer

The installer is responsible for complying with all the requirements provided by the manufacturer, together with everything required and provided for in the installation standards 650079-14, in terms of design envisaged by the designer, respecting all the limits of use of the equipment, performing instructions of the manufacturer, then installing the equipment, as supplied, without making any structural change, except of course to all the activities related to the connection with the underlying users, using only components certified and complying with the requirements of the aforementioned regulation.

The installer must use the cable entries prepared by the manufacturer and he will not be able to make additional holes for the installation of additional cable glands not initially foreseen. Recalling the above-mentioned OD 203, any modification made in disagreement with the prescriptions dictated by the manufacturer and in deviation of the provisions of the relevant regulations, in fact invalidate the certificate and compromise the functional safety.

6. The responsibility of the manager and the maintenance operator

Therefore, the manager and the maintenance operator of the plants where explosion-proof equipment is installed have a great responsibility, considering that the safety level of the equipment must be guaranteed by the manufacturer who certifies its suitability for the installation in certain areas, through the documentation required by the ATEX Directive 2014/34 / EU within the Community.

In this regard, it should be noted that the certifications of such equipment are issued by certification bodies qualified and accredited internationally and in EC. Furthermore, they are produced on the basis of a series of certification tests with components also certified and they must be accompanied by documents such as:

- EC type certificate;

- EU declaration of conformity;

- information necessary for a correct installation, use and maintenance, both for the single entity and if it is an assembly of entities assembled in the factory.

- the user and maintenance manual, listing all the rules that must be followed by the installer to ensure the maintenance of the essential safety requirements of the equipment, which must include at least:

o instructions for the correct use (area, temperature class, ambient temperature, limitations deriving from certificate conditions, etc.)

o installation method;

o verification and commissioning;

o requirements on the minimum maintenance requirements of the equipment (periodic tightening of electrical connections, restoration of grease on rolling joints, etc.)

o instructions on how to replace components, considering the above and complying with the provisions of OD 203, definition guide.

Once the installation has been completed, it will be necessary an initial check carried out in accordance with the provisions of regulation 60079-17 and, after the positive outcome of this verification, a periodic inspection plan. The maintenance company responsible for the maintenance of the plant and of the individual equipment is responsible for these aspects, in order to guarantee its correct functionality in the expected time, following the dictates of the regulation 60079-19.

Therefore, the maintenance technician cannot under any circumstances provide for the replacement of damaged parts without prior confrontation with the manufacturer in order to obtain the consent to change components.

Other clarification must be made in the event that the maintenance technician decides to replace the components without having complied with the above, which, in this case, would immediately invalidate the certificate and consequently imposing any and all liability on him, freeing the original constructor from any obligation.

7. Conclusions

With this very short exposition we only wanted to highlight the problems that exist in the regulatory environment for all the of design, management and maintenance operations that contribute to a good management of the plants and the functionality of the electro-instrumental equipment. We leave to the designer the task of analyzing all the multiple situations and implications deriving from the application of both the regulations and the laws in force in the country of destination of this equipment.